Patent application title: Apparatus for Recycling Noble Metals

Inventors:

Chin-Hsiung Yang (Da-Yuan Hsiang, TW)

Sin-Yi Tsai (Da-Yuan Hsiang, TW)

IPC8 Class: AC22B1100FI

USPC Class:

266114

Class name: Metallurgical apparatus having means for contacting a solid metalliferous material or metal object with a liquid

Publication date: 2010-03-11

Patent application number: 20100059909

vides an apparatus for recycling noble metals,

which comprises a conveyer, one or more carriers, an immersion device,

one or more dissolution devices, and one or more rinse devices. The

carriers carry objects containing noble metals. The conveyer is used for

conveying the carriers to the immersion device, the dissolution devices,

and the rinse devices sequentially for recycling noble metals from the

objects containing noble metals. The apparatus according to the present

invention can recycle noble metals continuously. Thereby, the speed of

recycling is enhanced, and the amount of recycled noble metals is

increased as well.Claims:

1. An apparatus for recycling noble metals, comprising:a conveyer;one or

more carriers, carrying an object containing noble metals, set on the

conveyer, and conveyed by the conveyer;an immersion device, containing a

solution, and the carrier carrying the object containing noble metals

immersing in the immersion device;one or more dissolution device,

containing a solution, the carrier immersing in the dissolution device

for dissolving, and the solution dissolving the noble metals contained in

the object containing noble metals; andone or more rinse device, rinsing

the carrier, and washing the noble metals out of the object containing

noble metals for recycling the noble metals from the dissolution device

and the rinse device.

2. The apparatus for recycling noble metals of claim 1, wherein the converyer is a hoist.

3. The apparatus for recycling noble metals of claim 1, and further comprising a control device, connecting to and controlling the conveyer.

4. The apparatus for recycling noble metals of claim 1, wherein the carrier further comprises a driving device, driving the carrier to spin.

5. The apparatus for recycling noble metals of claim 4, and further comprising a control device, connecting to and controlling the conveyer. And the driving device.

6. The apparatus for recycling noble metals of claim 1, wherein the carrier comprises:a body, having an opening, and the object containing noble metals being put from the opening; anda lid, set on the opening.

7. The apparatus for recycling noble metals of claim 1, wherein the carrier has a plurality of meshes.

8. The apparatus for recycling noble metals of claim 1, wherein the solution contained in the immersion device is water.

9. The apparatus for recycling noble metals of claim 1, wherein the immersion further comprises a drain, draining the solution contained in the immersion device.

10. The apparatus for recycling noble metals of claim 1, wherein the solution contained in the dissolution device can dissolve the noble metals.

11. The apparatus for recycling noble metals of claim 1, wherein a still device is further set between the immersion device and the dissolution device.

12. The apparatus for recycling noble metals of claim 1, wherein a still device is further set between the dissolution device and the rinse device.Description:

FIELD OF THE INVENTION

[0001]The present invention relates to a recycling apparatus, and particularly to an apparatus for recycling noble metals.

BACKGROUND OF THE INVENTION

[0002]With advancement of technologies, the electronics industry develops prosperously. Waste derived from electronic components increases daily. The waste includes integrated circuits, printed circuit board, resistors, or capacitors, and comprising elements of copper, lead, aluminum, iron, and noble metals. If the waste is not recycled and processed appropriately, the environment will be polluted and, from the perspective of fully utilizing the noble metals, it is invisible squander.

[0003]The recycling process of waste containing metals is mainly focused on recycling and reusing valuable metals including high-priced noble metals such as gold and palladium. For example, the waste containing gold comes from the integrated circuit industry and the printed circuit board industry. In the processes of thin-film deposition or metallization in the integrated circuit industry, a lot of waste containing gold is produced including replaced molds and derived waste from vapor deposition materials, waste liquid during gold metallization, waste wafers containing gold, gold powder, waste resins containing gold, waste catalyst containing gold, and waste iodine liquid containing gold, etc.

[0004]As the electronics industry progresses towards the trend of smaller, thinner, and more efficient, the selection and development of materials is crucial. For example, in the selection of electrode materials for multilayer ceramic capacitors, palladium is usually regarded as the electrode material of choice owing to its superior conductivity and low reactivity at high temperatures. However, because palladium is costly, it is important to recycle and reuse palladium effectively during the development of multilayer materials using palladium alloys.

[0005]Currently, there is no apparatus that can recycle noble metals systematically. In most cases, recycling of noble metals is performed manually. The present invention provides an apparatus for recycling noble metals systematically. Thereby, the speed of recycling is enhanced, and the amount of recycled noble metals is increased as well.

SUMMARY

[0006]An objective of the present invention is to provide an apparatus for recycling noble metals, which can recycle noble metals continuously. Thereby, the speed of recycling is enhanced, and the amount of recycled noble metals is increased as well.

[0007]Another objective of the present invention is to provide an apparatus for recycling noble metals, which can recycle noble metals automatically.

[0008]In order to achieve the objectives described above, the present invention provides an apparatus for recycling noble metals, which comprises a conveyer, one or more carriers, an immersion device, one or more dissolution devices, and one or more rinse devices. The carriers are set on the conveyer, which conveys the carriers to the immersion device, the dissolution devices, or the rinse devices. The carriers carry objects containing noble metals, and are conveyed to the immersion device, the dissolution devices, and the rinse devices sequentially by the conveyer for recycling noble metals.

BRIEF DESCRIPTION OF THE DRAWINGS

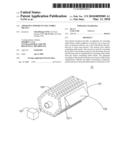

[0009]FIG. 1 shows a schematic diagram of an apparatus according to a preferred embodiment of the present invention;

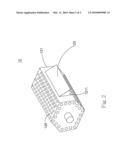

[0010]FIG. 2 shows a schematic diagram of a carrier according to a preferred embodiment of the present invention;

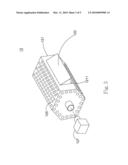

[0011]FIG. 3 shows a schematic diagram of a carrier according to another preferred embodiment of the present invention;

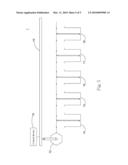

[0012]FIG. 4 shows a schematic diagram of an immersion device according to another preferred embodiment of the present invention; and

[0013]FIG. 5 shows a schematic diagram of an apparatus according to another preferred embodiment of the present invention.

DETAILED DESCRIPTION

[0014]In order to make the structure and characteristics as well as the effectiveness of the present invention to be further understood and recognized, the detailed description of the present invention is provided as follows along with preferred embodiments and accompanying figures.

[0015]FIG. 1 shows a schematic diagram of an apparatus according to a preferred embodiment of the present invention. As shown in the figure, the present invention provides an apparatus for recycling noble metals 1, which comprises a conveyer 10, one or more carriers 12, an immersion device 14, one or more dissolution devices 16, and one or more rinse devices 18. The conveyer 10 is a hoist, used for conveying the carrier 12 to the immersion device 14, the dissolution devices 16, or the rinse devices 18.

[0016]FIG. 2 shows a schematic diagram of a carrier according to a preferred embodiment of the present invention. As shown in the figure, the carrier 12 carries an object containing noble metals, and comprises a body 121 and a lid 123. The body 121 has an opening 1211, from which the object containing noble metals is put into the body 121. The carrier 12 has a plurality of meshes 125. The carrier 12 carrying the object containing noble metals is conveyed to the immersion device 14 by the conveyer 10. The immersion device 14 contains a solution, which is water. When the carrier 12 carrying the object containing noble metals is immersed into the solution contained by the immersion device 14, the solution enters the carrier 12 via the plurality of meshes 125 thereof, and the object containing noble metals will be soaked and spread.

[0017]Next, pull up the carrier 12 immersed in the immersion device 14 by means of the conveyer 10. The conveyer 10 then conveys the carrier 12 to the dissolution device 16. The dissolution device 16 contains a solution, which can dissolve one or more noble metals contained in the object containing noble metals. When the carrier 12 is immersed in the solution contained in the dissolution device 16, the solution can dissolve noble metals contained in the object containing noble metals, and leave the object containing few noble metals in the carrier 12.

[0018]Finally, pull up the carrier 12 immersed in the dissolution device 16 by means of the conveyer 10. The conveyer 10 then conveys the carrier 12 containing the object containing few noble metals to the rinse device 18. The rinse device 18 rinses the object containing few noble metals and residual noble metals left on the object carried by the carrier 12. Thereby, noble metals can be recycled from the solution contained in the dissolution device 16 and the rinse device 18. It is known from above description that the apparatus for recycling noble metals 1 according to the present invention has a plurality of carriers 12, and can use the conveyer 10 to perform immersion, dissolution, and rinse procedures sequentially.

[0019]FIG. 3 shows a schematic diagram of a carrier according to another preferred embodiment of the present invention. As shown in the figure, in order to make the object containing noble metals be soaked, spread, and dissolved uniformly and to make the object containing few noble metals be rinsed uniformly, the carrier 12 further comprises a driving device 127, which can drive the carrier 12 to spin.

[0020]FIG. 4 shows a schematic diagram of an immersion device according to another preferred embodiment of the present invention. As shown in the figure, the immersion device 14 further has a drain 141 set at the bottom of the immersion device 14. When the carrier 12 is pulled up from the immersion device 14, the solution contained in the immersion device 14 is drained to the drain 141 from the bottom of the immersion device 14.

[0021]FIG. 5 shows a schematic diagram of an apparatus according to another preferred embodiment of the present invention. As shown in the figure, the present preferred embodiment provides an apparatus for recycling noble metals 1 automatically, which comprises a conveyer 10, one or more carriers 12, an immersion device 14, one or more dissolution devices 16, and one or more rinse devices 18. In order to make the apparatus for recycling noble metals 1 operate automatically, the apparatus for recycling noble metals 1 further comprises a control device 12, which is connected to the conveyer 10, and controls the conveyer 10 to convey the conveyer 12. In addition, a still device 15 is set between the immersion device 14 and the dissolution device 16; a still device 17 is set between the dissolution device 16 and the rinse device 18.

[0022]The conveyer 10 conveys the carrier 12 to the immersion device 14, the dissolution device 16, or the rinse device 18. The carrier 12 carries an object containing noble metals. The carrier 12 carrying the object containing noble metals is conveyed to the immersion device 14 by the conveyer 10. The immersion device 14 contains a solution, which is water. When the carrier 12 carrying the object containing noble metals is immersed into the solution contained by the immersion device 14, the object containing noble metals will be soaked and spread.

[0023]Next, pull up the carrier 12 immersed in the immersion device 14 by means of the conveyer 10. The conveyer 10 then conveys the carrier 12 to the still device 15 and still for a while. Afterwards, the conveyer 10 conveys the carrier 12 to the dissolution device 16. The dissolution device 16 contains a solution, which can dissolve one or more noble metals contained in the object containing noble metals. When the carrier 12 is immersed in the solution contained in the dissolution device 16, the solution can dissolve noble metals contained in the object containing noble metals, and leave the object containing few noble metals in the carrier 12.

[0024]Finally, pull up the carrier 12 immersed in the dissolution device 16 by means of the conveyer 10. The conveyer 10 then conveys the carrier 12 to the still device 17 and still for a while. Afterwards, the conveyer 10 conveys the carrier 12 containing the object containing few noble metals to the rinse device 18. The rinse device 18 rinses the object containing few noble metals and residual noble metals left on the object carried by the carrier 12. Thereby, noble metals can be recycled from the solution contained in the dissolution device 16 and the rinse device 18. The apparatus for recycling noble metals 1 according to the present preferred embodiment has a plurality of carriers 12, and can use the conveyer 10 to hoist the carriers 12 and to perform immersion, still, dissolution, still, and rinse procedures sequentially.

[0025]As shown in FIG. 3, in order to make the object containing noble metals be soaked, spread, and dissolved uniformly and to make the object containing few noble metals be rinsed uniformly, the carrier 12 further comprises a driving device 127, which is connected to the control device 19. The control device 19 controls the driving device 127, and the driving device 127 drives the carrier 12 to spin.

[0026]To sum up, the present invention provides an apparatus for recycling noble metals, which can recycle noble metals continuously. The apparatus for recycling noble metals is an automatic apparatus. Thereby, the speed of recycling is enhanced, and the amount of recycled noble metals is increased as well.

[0027]Accordingly, the present invention conforms to the legal requirements owing to its novelty, non-obviousness, and utility. However, the foregoing description is only a preferred embodiment of the present invention, not used to limit the scope and range of the present invention. Those equivalent changes or modifications made according to the shape, structure, feature, or spirit described in the claims of the present invention are included in the appended claims of the present invention.

Claims:

1. An apparatus for recycling noble metals, comprising:a conveyer;one or

more carriers, carrying an object containing noble metals, set on the

conveyer, and conveyed by the conveyer;an immersion device, containing a

solution, and the carrier carrying the object containing noble metals

immersing in the immersion device;one or more dissolution device,

containing a solution, the carrier immersing in the dissolution device

for dissolving, and the solution dissolving the noble metals contained in

the object containing noble metals; andone or more rinse device, rinsing

the carrier, and washing the noble metals out of the object containing

noble metals for recycling the noble metals from the dissolution device

and the rinse device.

2. The apparatus for recycling noble metals of claim 1, wherein the converyer is a hoist.

3. The apparatus for recycling noble metals of claim 1, and further comprising a control device, connecting to and controlling the conveyer.

4. The apparatus for recycling noble metals of claim 1, wherein the carrier further comprises a driving device, driving the carrier to spin.

5. The apparatus for recycling noble metals of claim 4, and further comprising a control device, connecting to and controlling the conveyer. And the driving device.

6. The apparatus for recycling noble metals of claim 1, wherein the carrier comprises:a body, having an opening, and the object containing noble metals being put from the opening; anda lid, set on the opening.

7. The apparatus for recycling noble metals of claim 1, wherein the carrier has a plurality of meshes.

8. The apparatus for recycling noble metals of claim 1, wherein the solution contained in the immersion device is water.

9. The apparatus for recycling noble metals of claim 1, wherein the immersion further comprises a drain, draining the solution contained in the immersion device.

10. The apparatus for recycling noble metals of claim 1, wherein the solution contained in the dissolution device can dissolve the noble metals.

11. The apparatus for recycling noble metals of claim 1, wherein a still device is further set between the immersion device and the dissolution device.

12. The apparatus for recycling noble metals of claim 1, wherein a still device is further set between the dissolution device and the rinse device.

Description:

FIELD OF THE INVENTION

[0001]The present invention relates to a recycling apparatus, and particularly to an apparatus for recycling noble metals.

BACKGROUND OF THE INVENTION

[0002]With advancement of technologies, the electronics industry develops prosperously. Waste derived from electronic components increases daily. The waste includes integrated circuits, printed circuit board, resistors, or capacitors, and comprising elements of copper, lead, aluminum, iron, and noble metals. If the waste is not recycled and processed appropriately, the environment will be polluted and, from the perspective of fully utilizing the noble metals, it is invisible squander.

[0003]The recycling process of waste containing metals is mainly focused on recycling and reusing valuable metals including high-priced noble metals such as gold and palladium. For example, the waste containing gold comes from the integrated circuit industry and the printed circuit board industry. In the processes of thin-film deposition or metallization in the integrated circuit industry, a lot of waste containing gold is produced including replaced molds and derived waste from vapor deposition materials, waste liquid during gold metallization, waste wafers containing gold, gold powder, waste resins containing gold, waste catalyst containing gold, and waste iodine liquid containing gold, etc.

[0004]As the electronics industry progresses towards the trend of smaller, thinner, and more efficient, the selection and development of materials is crucial. For example, in the selection of electrode materials for multilayer ceramic capacitors, palladium is usually regarded as the electrode material of choice owing to its superior conductivity and low reactivity at high temperatures. However, because palladium is costly, it is important to recycle and reuse palladium effectively during the development of multilayer materials using palladium alloys.

[0005]Currently, there is no apparatus that can recycle noble metals systematically. In most cases, recycling of noble metals is performed manually. The present invention provides an apparatus for recycling noble metals systematically. Thereby, the speed of recycling is enhanced, and the amount of recycled noble metals is increased as well.

SUMMARY

[0006]An objective of the present invention is to provide an apparatus for recycling noble metals, which can recycle noble metals continuously. Thereby, the speed of recycling is enhanced, and the amount of recycled noble metals is increased as well.

[0007]Another objective of the present invention is to provide an apparatus for recycling noble metals, which can recycle noble metals automatically.

[0008]In order to achieve the objectives described above, the present invention provides an apparatus for recycling noble metals, which comprises a conveyer, one or more carriers, an immersion device, one or more dissolution devices, and one or more rinse devices. The carriers are set on the conveyer, which conveys the carriers to the immersion device, the dissolution devices, or the rinse devices. The carriers carry objects containing noble metals, and are conveyed to the immersion device, the dissolution devices, and the rinse devices sequentially by the conveyer for recycling noble metals.

BRIEF DESCRIPTION OF THE DRAWINGS

[0009]FIG. 1 shows a schematic diagram of an apparatus according to a preferred embodiment of the present invention;

[0010]FIG. 2 shows a schematic diagram of a carrier according to a preferred embodiment of the present invention;

[0011]FIG. 3 shows a schematic diagram of a carrier according to another preferred embodiment of the present invention;

[0012]FIG. 4 shows a schematic diagram of an immersion device according to another preferred embodiment of the present invention; and

[0013]FIG. 5 shows a schematic diagram of an apparatus according to another preferred embodiment of the present invention.

DETAILED DESCRIPTION

[0014]In order to make the structure and characteristics as well as the effectiveness of the present invention to be further understood and recognized, the detailed description of the present invention is provided as follows along with preferred embodiments and accompanying figures.

[0015]FIG. 1 shows a schematic diagram of an apparatus according to a preferred embodiment of the present invention. As shown in the figure, the present invention provides an apparatus for recycling noble metals 1, which comprises a conveyer 10, one or more carriers 12, an immersion device 14, one or more dissolution devices 16, and one or more rinse devices 18. The conveyer 10 is a hoist, used for conveying the carrier 12 to the immersion device 14, the dissolution devices 16, or the rinse devices 18.

[0016]FIG. 2 shows a schematic diagram of a carrier according to a preferred embodiment of the present invention. As shown in the figure, the carrier 12 carries an object containing noble metals, and comprises a body 121 and a lid 123. The body 121 has an opening 1211, from which the object containing noble metals is put into the body 121. The carrier 12 has a plurality of meshes 125. The carrier 12 carrying the object containing noble metals is conveyed to the immersion device 14 by the conveyer 10. The immersion device 14 contains a solution, which is water. When the carrier 12 carrying the object containing noble metals is immersed into the solution contained by the immersion device 14, the solution enters the carrier 12 via the plurality of meshes 125 thereof, and the object containing noble metals will be soaked and spread.

[0017]Next, pull up the carrier 12 immersed in the immersion device 14 by means of the conveyer 10. The conveyer 10 then conveys the carrier 12 to the dissolution device 16. The dissolution device 16 contains a solution, which can dissolve one or more noble metals contained in the object containing noble metals. When the carrier 12 is immersed in the solution contained in the dissolution device 16, the solution can dissolve noble metals contained in the object containing noble metals, and leave the object containing few noble metals in the carrier 12.

[0018]Finally, pull up the carrier 12 immersed in the dissolution device 16 by means of the conveyer 10. The conveyer 10 then conveys the carrier 12 containing the object containing few noble metals to the rinse device 18. The rinse device 18 rinses the object containing few noble metals and residual noble metals left on the object carried by the carrier 12. Thereby, noble metals can be recycled from the solution contained in the dissolution device 16 and the rinse device 18. It is known from above description that the apparatus for recycling noble metals 1 according to the present invention has a plurality of carriers 12, and can use the conveyer 10 to perform immersion, dissolution, and rinse procedures sequentially.

[0019]FIG. 3 shows a schematic diagram of a carrier according to another preferred embodiment of the present invention. As shown in the figure, in order to make the object containing noble metals be soaked, spread, and dissolved uniformly and to make the object containing few noble metals be rinsed uniformly, the carrier 12 further comprises a driving device 127, which can drive the carrier 12 to spin.

[0020]FIG. 4 shows a schematic diagram of an immersion device according to another preferred embodiment of the present invention. As shown in the figure, the immersion device 14 further has a drain 141 set at the bottom of the immersion device 14. When the carrier 12 is pulled up from the immersion device 14, the solution contained in the immersion device 14 is drained to the drain 141 from the bottom of the immersion device 14.

[0021]FIG. 5 shows a schematic diagram of an apparatus according to another preferred embodiment of the present invention. As shown in the figure, the present preferred embodiment provides an apparatus for recycling noble metals 1 automatically, which comprises a conveyer 10, one or more carriers 12, an immersion device 14, one or more dissolution devices 16, and one or more rinse devices 18. In order to make the apparatus for recycling noble metals 1 operate automatically, the apparatus for recycling noble metals 1 further comprises a control device 12, which is connected to the conveyer 10, and controls the conveyer 10 to convey the conveyer 12. In addition, a still device 15 is set between the immersion device 14 and the dissolution device 16; a still device 17 is set between the dissolution device 16 and the rinse device 18.

[0022]The conveyer 10 conveys the carrier 12 to the immersion device 14, the dissolution device 16, or the rinse device 18. The carrier 12 carries an object containing noble metals. The carrier 12 carrying the object containing noble metals is conveyed to the immersion device 14 by the conveyer 10. The immersion device 14 contains a solution, which is water. When the carrier 12 carrying the object containing noble metals is immersed into the solution contained by the immersion device 14, the object containing noble metals will be soaked and spread.

[0023]Next, pull up the carrier 12 immersed in the immersion device 14 by means of the conveyer 10. The conveyer 10 then conveys the carrier 12 to the still device 15 and still for a while. Afterwards, the conveyer 10 conveys the carrier 12 to the dissolution device 16. The dissolution device 16 contains a solution, which can dissolve one or more noble metals contained in the object containing noble metals. When the carrier 12 is immersed in the solution contained in the dissolution device 16, the solution can dissolve noble metals contained in the object containing noble metals, and leave the object containing few noble metals in the carrier 12.

[0024]Finally, pull up the carrier 12 immersed in the dissolution device 16 by means of the conveyer 10. The conveyer 10 then conveys the carrier 12 to the still device 17 and still for a while. Afterwards, the conveyer 10 conveys the carrier 12 containing the object containing few noble metals to the rinse device 18. The rinse device 18 rinses the object containing few noble metals and residual noble metals left on the object carried by the carrier 12. Thereby, noble metals can be recycled from the solution contained in the dissolution device 16 and the rinse device 18. The apparatus for recycling noble metals 1 according to the present preferred embodiment has a plurality of carriers 12, and can use the conveyer 10 to hoist the carriers 12 and to perform immersion, still, dissolution, still, and rinse procedures sequentially.

[0025]As shown in FIG. 3, in order to make the object containing noble metals be soaked, spread, and dissolved uniformly and to make the object containing few noble metals be rinsed uniformly, the carrier 12 further comprises a driving device 127, which is connected to the control device 19. The control device 19 controls the driving device 127, and the driving device 127 drives the carrier 12 to spin.

[0026]To sum up, the present invention provides an apparatus for recycling noble metals, which can recycle noble metals continuously. The apparatus for recycling noble metals is an automatic apparatus. Thereby, the speed of recycling is enhanced, and the amount of recycled noble metals is increased as well.

[0027]Accordingly, the present invention conforms to the legal requirements owing to its novelty, non-obviousness, and utility. However, the foregoing description is only a preferred embodiment of the present invention, not used to limit the scope and range of the present invention. Those equivalent changes or modifications made according to the shape, structure, feature, or spirit described in the claims of the present invention are included in the appended claims of the present invention.

User Contributions:

Comment about this patent or add new information about this topic: