Patent application title: MULTI-PHASE DOWN HOLE INJECTOR

Inventors:

Ganlu Liu (Yangzhou, CN)

Yiqun Zhang (Yangzhou, CN)

Ya Liu (Yangzhou, CN)

Bo Chen (Yangzhou, CN)

Tao Ke (Yangzhou, CN)

Chengxing Chong (Yangzhou, CN)

IPC8 Class: AE21B4312FI

USPC Class:

166299

Class name: Wells processes with explosion or breaking container to implode

Publication date: 2012-11-29

Patent application number: 20120298364

Abstract:

A multi-phase down hole injector related to a down hole tool for oilfield

well drilling, has a shooting pipe, an axial hole disposed in the center

of the shooting pipe, one end of the shooting pipe is connected to an

ellipsoid guide, at least two housing seats sets are disposed along the

shooting pipe, every housing seat set are disposed with at least two

housing seats of radial symmetry, the inner ends of every housing seat is

separately connected to the axial hole, every housing seat is disposed

with a injection barrel by the base, and the explosive cavity is disposed

between the base and the housing seat. The injected viscosity fluid can

exert squeezing and shearing force to the rock to make the channel and

breach smaller or eliminated.Claims:

1. A multi-phase down hole injector, wherein includes a shooting pipe, an

axial hole is disposed in the center of the shooting pipe, one end of the

shooting pipe is connected to an ellipsoid guide, at least two housing

seats sets are disposed along the shooting pipe, every housing seat set

are disposed with at least two housing seats of radial symmetry, the

inner ends of every housing seat is separately connected to the axial

hole, every housing seat is disposed with a injection barrel by the base,

and the explosive cavity is disposed between the base and the housing

seat.

2. A multi-phase down hole injector according to the claim 1, wherein the base is disposed in the inner end of the housing seat, while the injection barrel is disposed in the outer end of the housing seat; the inner end of the injection barrel is thread connected to the outer end of the base, the front end and the side wall of the injection barrel are separately disposed with hole connected to the injection barrel.

3. A multi-phase down hole injector according to the claim 1, wherein the outer end of the injection barrel is protruded out of the shooting pipe surface, and the distance between the outer end of the injection barrel and the centre shaft of the shooting pipe is shorter than the distance between the maximum overall diameter of the ellipsoid guide and the centre shaft of the shooting pipe.

4. A multi-phase down hole injector according to the claim 1, wherein both ends of the shooting pipe are disposed with pin thread and box thread of coupled to each other.

5. A multi-phase down hole injector according to the claim 4, wherein the guide is thread connected to the shooting pipe.

6. A multi-phase down hole injector according to the claim 1, wherein every housing seat sets has three housing seats 14 of radial symmetry, the housing seat is stepped hole, the inner end of which is small hole, the small hole is connected to the axial hole 13 each, the extending of the small hole outwards is centre hole, and the outer end is big hole; the base is disposed inside the housing seat, and positioned by the lower surface of the big hole; the injection barrel is disposed on the base, the explosive cavity is disposed between the base and the housing seat.

7. A wellbore wall strengthening methods adopted with the multi-phase down hole injector according to the claim 1, wherein includes steps below: Explosive loading: put the rubber pipe into the injection barrel of the multi-phase down hole injector of the present invention, install the explosive into the explosive cavity; set the critical cable inside the centre axial hole of the shooting pipe, connect one end of the critical cable to the explosive inside the explosive cavity, lead the other end to the explosive actuator; Down hole: put the ellipsoid guide faced downwards; connect the shooting pipe to the drill pipe to let the shooting pipe with explosive down hole; Detonating: when the shooting pipe reaches to the preset position down hole, light the critical cable to detonate the explosive charge by the liquid in the drill pipe forcing the explosive actuator or by the surface explosive actuator controller, the injection barrel injects into the wellbore by the explosive, and the viscosity fluid pipe is broken crowded by the rock, the viscosity fluid is entered into the rock crack to strengthen the wellbore.

Description:

FIELD OF THE INVENTION

[0001] The present invention relates to a down hole tool for oilfield well drilling, especially to a multi-function tool which can plug the losses in hole and strengthen the wellbore wall and a wellbore wall strengthening methods.

BACKGROUND OF THE INVENTION

[0002] Circulation loss is often encountered while drilling operation is ongoing; a slight loss may break drilling operation, while serious loss may waste a great deal of time, and even man-hour and material cost. If a loss cannot be handled in a timely manner, more down hole problems will arise subsequently, such as cave in, blowout and stuck pipe, which will result in sections or the whole wellbore getting un-recoverable. Therefore, to cure the loss in a timely manner and resume the drilling operation is very critical. Secondly, in the operation of cementing job, some sections of the wellbore is not strong enough to stand the hydrostatic pressure of the cement slurry, which may again cause a loss in the hole, or a failure of cementing job. In this case, it is necessary to strengthen the weak sections of the wellbore.

SUMMARY OF THE INVENTION

[0003] The object of the present invention is to provide with a multi-phase down hole injector, which can seal the losing breaches of the wall by injecting the viscosity fluid, exerting squeezing and shearing force to the rocks to make the breaches shrunk or eliminated, and then plug the well loss.

[0004] The technical proposal of the present invention is that: the present invention includes a shooting pipe, an axial hole is disposed in the center of the shooting pipe, one end of the shooting pipe is connected to an ellipsoid guide, at least two housing seats sets are disposed along the shooting pipe, every housing seat set are disposed with at least two housing seats of radial symmetry, the inner ends of every housing seat is separately connected to the axial hole, every housing seat is disposed with a injection barrel by the base, and the explosive cavity is disposed between the base and the housing seat.

[0005] Another technical proposal of the present invention is: a wellbore wall strengthening methods includes steps below:

Explosive charge loading: put the rubber pipe into the injection barrel of the multi-phase down hole injector of the present invention, install the explosive charge into the explosive cavity; set the critical cable inside the centre axial hole of the shooting pipe, connect one end of the critical cable to the explosive inside the explosive cavity, lead the other end to the explosive actuator; Down hole: put the ellipsoid guide faced downwards; connect the shooting pipe to the drill pipe to let the shooting pipe with explosive down hole; Detonating: when the shooting pipe reaches to the preset position down hole, light the critical cable to detonate the explosive charge by the liquid in the drill pipe forcing the explosive actuator or by the surface explosive actuator controller, the injection barrel injects into the wellbore by the explosive, and the viscosity fluid pipe is broken crowded by the rock, the viscosity fluid is entered into the rock crack to strengthen the wellbore.

[0006] The present invention is simple in structure and easy to operate. The injected viscosity fluid can exert squeezing and shearing force to the rock to make the channel and breach smaller or eliminated. Quick and efficient in strengthening the wellbore, it can prevent loss and safeguard the oilfield.

[0007] For the convenience of down hole operation, the base of the present invention is disposed in the inner end of the housing seat, while the injection barrel is disposed at the outer end of the housing seat. The inner end of injection barrel is thread connected to the outer end of the housing seat, and the inner front end and the side wall of the injection barrel are disposed with several through holes.

[0008] In order to avoid any detachment of injection barrel from the body caused by bumps against the wellbore, the outer end of the injection barrel is protruded out of the surface of shooting pipe. The distance between the outer end of the injection barrel and the centre shaft of the shooting pipe is shorter than the distance between the maximum overall diameter of the ellipsoid guide and the centre shaft of the shooting pipe.

[0009] As matched pin thread and box thread connection are disposed in the shooting pipe, several shooting pipes can be connected together to strengthen long section of the wellbore.

[0010] The guide is thread connected to the shooting pipe, and is placed below the lowest shooting pipe.

BRIEF DESCRIPTION OF THE DRAWINGS

[0011] FIG. 1 illustrates the structural of the embodiment of the present invention of a multi-phase down hole injector;

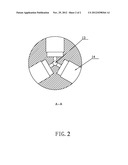

[0012] FIG. 2 illustrates the sectional view of the shooting pipe at A-A.

DETAILED DESCRIPTION OF THE EMBODIMENTS

[0013] As figured in the FIG. 1 and FIG. 2 is a multi-phase down hole injector of the present invention, in which the shooting pipe 1 is disposed with box thread 11 at the left end for connected to the drill pipe or the second shooting pipe 5, while with pin thread 12 at the right end for thread connected to the ellipsoid guide 2 or the third shooting pipe.

[0014] An axial hole is disposed at the centre of the shooting pipe 1, at least two housing seat sets are disposed along the shooting pipe 1. every housing seat sets has three housing seats 14 of radial symmetry. every housing seat is stepped holes, the inner end of which is small hole separately connected to the axial hole 13. the extending of the small hole outwards is centre hole, and the outer end is big hole.

[0015] The inner end of the housing seats 14 is disposed with a base 3, which is positioned by the lower surface of the big hole. The injection barrel 4 is disposed at the outer end of the housing seat 14, and the inner end of the injection barrel 4 is thread connected to the outer end of the base 3. the front end and the side wall of the injection barrel 4 are separately disposed with holes 41, 42 connected to the central of the injection barrel 4. the explosive cavity 31 is disposed between the base 3 and the housing seat 14. the outer end of the injection barrel 4 is protruded out of the shooting pipe 1 surface. The distance between the outer end of the injection barrel 4 and the centre shaft of the shooting pipe 1 is shorter than the distance between the maximum overall diameter of the ellipsoid guide 2 and the centre shaft of the shooting pipe 1.

[0016] A wellbore wall strengthening methods of present invention includes steps below:

Explosive loading: put the rubber pipe into the injection barrel 4 of the multi-phase down hole injector of the present invention, install the explosive into the explosive cavity 31. set the critical cable inside the centre axial hole 13 of the shooting pipe 1, connect one end of the critical cable to the explosive inside the explosive cavity, lead the other end to the explosive actuator; Down hole: put the ellipsoid guide 2 faced downward, connect the shooting pipe 1 to the drill pipe to let the shooting pipe with explosive down hole; Detonating: when the shooting pipe 1 reaches to the preset position down hole, light the critical cable to detonate the explosive by the liquid in the drill pipe forcing the explosive actuator or by the surface explosive actuator controller, the injection barrel 4 injects into the wellbore wall by the explosive, and the viscosity fluid pipe is broken crowded by the rock, the viscosity fluid is entered into the rock crack to strengthen the wellbore wall.

INDUSTRIAL APPLICABILITY

[0017] The present invention is provided with a multi-phase down hole injector and a wellbore wall strengthening methods, which is simple in structure and easy to operate. The injected viscosity fluid can exert squeezing and shearing force to the rock to make the channel and breach smaller or eliminated. Quick and efficient in strengthening the wellbore, it can prevent loss and safeguard the oilfield with well industrial applicability.

User Contributions:

Comment about this patent or add new information about this topic:

| People who visited this patent also read: | |

| Patent application number | Title |

|---|---|

| 20190217266 | METHODS OF SULFURIZING METAL CONTAINING PARTICLES |

| 20190217265 | SURFACTANT COMPOSITION |

| 20190217264 | PERSONAL WATER ENHANCEMENT DEVICE |

| 20190217263 | Suckabucket |

| 20190217262 | Bone Cement Mixing Apparatus and Method Therefor |