Patent application title: DRIVING DEVICE AND PROTECTION METHOD THEREOF

Inventors:

Song-Ling Yang (Shenzhen City, CN)

Assignees:

HONG FU JIN PRECISION INDUSTRY (ShenZhen) CO., LTD .

HON HAI PRECISION INDUSTRY CO., LTD.

IPC8 Class: AH02H7085FI

USPC Class:

361 23

Class name: Electricity: electrical systems and devices safety and protection of systems and devices motor protective condition responsive circuits

Publication date: 2010-09-09

Patent application number: 20100226052

a motor, a clutch gear, a first rotating

portion, a second rotating portion, a piezoelectric assembly, and a

controlling unit. The motor includes a rotating shaft. The clutch gear is

fixed to the rotating shaft. The first rotating portion sleeved on the

rotating shaft includes a first end meshing with the clutch gear and a

second end opposite to the first end. The second rotating portion is

engaged with the second end. The piezoelectric assembly is sandwiched

between the second end and the second rotating portion. The controlling

unit is electrically connected to the motor and the piezoelectric

assembly. The controlling unit is configured for storing a predetermined

voltage, and determining whether a voltage output by the piezoelectric

assembly equals to or exceeds the predetermined voltage. A protection

method for the driving device is also provided.Claims:

1. A driving device comprising:a motor comprising a rotating shaft;a

clutch gear fixed to the rotating shaft;a first rotating portion sleeved

on the rotating shaft corresponding to the clutch gear, the first

rotating portion comprising a first end meshing with the clutch gear and

a second end opposite to the first end;a second rotating portion engaged

with the second end of the first rotating portion;a piezoelectric

assembly sandwiched between the second end of the first rotating portion

and the second rotating portion so that the piezoelectric assembly is

capable of sensing an axial force applied to the second rotating portion

by the first rotating portion, the piezoelectric assembly being capable

of converting the axial force into a voltage; anda controlling unit

electrically connected to the motor and the piezoelectric assembly, the

controlling unit configured for storing a predetermined voltage, and for

determining whether the voltage output by the piezoelectric assembly

equals to or exceeds the predetermined voltage and for deactivating the

motor if the voltage output by the piezoelectric assembly equals to or

exceeds the predetermined voltage.

2. The driving device as claimed in claim 1, wherein the first end is a cylinder, and a plurality of teeth are formed in the first end to mesh with the clutch gear.

3. The driving device as claimed in claim 1, wherein the shape of the second end is approximately a regular-hexagonal-prism, the second end comprises an outer bottom surface, a receiving cavity is defined in the second rotating portion corresponding to the first rotating portion, the second rotating portion comprises an inner bottom surface in the receiving cavity, and the piezoelectric assembly is sandwiched between the outer bottom surface and the inner bottom surface.

4. The driving device of claim 1, wherein the piezoelectric assembly comprises two electrode plates and a piezoelectric plate sandwiched between the two electrode plates.

5. The driving device of claim 1, wherein the controlling unit comprises a voltage detector configured for detecting the voltage output by the piezoelectric assembly, a memory configured for storing the predetermined voltage and a controller configured for determining whether the detected voltage equals to or exceeds the predetermined voltage and deactivating the motor if the detected voltage equals to or exceeds the predetermined voltage.

6. A protection method for a driving device, the driving device comprising a motor comprising a rotating shaft, a clutch gear fixed to the rotating shaft, a first rotating portion sleeved on the rotating shaft, a second rotating portion engaged with the first rotating portion and a piezoelectric assembly sandwiched between the first rotating portion and the second rotating portion so that the piezoelectric assembly is capable of sensing the axial force applied to the second rotating portion by the first rotating portion, the piezoelectric assembly being capable of converting the axial force into a voltage, the method comprising:detecting the voltage output by the piezoelectric assembly;determining whether the detected voltage equals to or exceeds a predetermined voltage; anddeactivating the motor if the detected voltage equals to or exceeds the predetermined voltage.

7. The protection method of claim 6, further comprising repeating the step of detecting the voltage output by the piezoelectric assembly if the detected voltage is lower than the predetermined voltage.

8. The protection method of claim 6, further comprising reactivating the motor after a predetermined time and repeating the step of detecting the voltage output by the piezoelectric assembly.Description:

BACKGROUND

[0001]1. Technical Field

[0002]The present disclosure relates to driving technology and, particularly, to a driving device and a protection method thereof.

[0003]2. Description of Related Art

[0004]Motors are found in many appliances. In these appliances, it is not uncommon that the load on these motors suddenly increases and goes beyond the power rating of the motors. In these cases, the motors are overloaded while still powered on, and the motors can be damaged under this condition.

[0005]Therefore, what is needed is to provide a driving device and a protection method thereof, in which the above-mention problem is eliminated or at least alleviated.

BRIEF DESCRIPTION OF THE DRAWINGS

[0006]FIG. 1 is a schematic isometric view of a driving device including a controlling unit, according to a first exemplary embodiment.

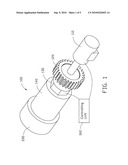

[0007]FIG. 2 is an exploded schematic isometric view of the driving device of FIG. 1.

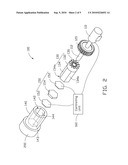

[0008]FIG. 3 is a partial exploded schematic isometric view of the driving device of FIG. 1, but viewed from another angle.

[0009]FIG. 4 is a functional block diagram of the controlling unit of FIG. 1.

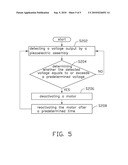

[0010]FIG. 5 is a flowchart of a protection method, according to a second exemplary embodiment.

DETAILED DESCRIPTION

[0011]Referring to FIGS. 1-3, a driving device 100, according to a first exemplary embodiment, includes a motor 110, a clutch gear 120, a first rotating portion 130, a second rotating portion 140, a piezoelectric assembly 150, and a controlling unit 160. The motor 110 includes a rotating shaft 112, which rotates when the motor 110 is powered on. The clutch gear 120 is fixed to the rotating shaft 112 and rotates with the rotating shaft 112. A number of teeth 122 (FIG. 3) are formed in one side of the clutch gear 120.

[0012]The first rotating portion 130 is hollow and sleeved on the rotating shaft 112. The first rotating portion 130 includes a first end 132 and a second end 134. The first end 132 is a cylinder. A number of teeth 136 are formed in an end surface of the first end 132 to mesh with the number of teeth 122 of the clutch gear 120. The first rotating portion 130 is rotated following the rotation of the clutch gear 120 and is pressed by an axial force from the clutch gear 120 to move toward the second rotating portion 140. The shape of the second end 134 is approximately a regular-hexagonal-prism. The second end 134 includes an outer bottom surface 134a and six outer side surfaces 134b.

[0013]The second rotating portion 140 is a hollow cylinder, and coupled to a load 200. A receiving cavity 142 is defined in the second rotating portion 140, corresponding to the first rotating portion 130. The shape of the receiving cavity 142 is approximately a regular-hexagonal-prism corresponding to the first rotating portion 130 so that the second rotating portion 140 can engagingly mate with the first rotating portion 130 and be driven by the first rotating portion 130 to rotate. The receiving cavity 142 is bounded by an inner bottom surface 143 and six inner side surfaces 144 of the second rotating portion 140. The inner bottom surface 143 corresponds to the outer bottom surface 134a. The six inner side surfaces 144 correspond to the six outer side surfaces 134b, respectively.

[0014]The piezoelectric assembly 150 is sandwiched between the outer bottom surface 134a and the inner bottom surface 143. The piezoelectric assembly 150 is capable of sensing the axial force applied to the second rotating portion 140 by the first rotating portion 130 and the piezoelectric assembly 150 is capable of converting the axial force into a voltage. In this embodiment, the piezoelectric assembly 150 includes two electrode plates 152 and a piezoelectric plate 154 sandwiched between the two electrode plates 152. When the second rotating portion 140 is rotated by the first rotating portion 130, the first rotating portion 130 is pressed by the clutch gear 120 to apply the axial force on the second rotating portion 140, as a result, the piezoelectric plate 154 becomes deformed and outputs the voltage indicative of the intensity of the axial force by the two electrode plates 152.

[0015]The controlling unit 160 is electrically connected to the two electrode plates 152 and the motor 110. Referring to FIG. 4 together with FIG. 2, the controlling unit 160 includes a voltage detector 162, a memory 164, and a controller 166.

[0016]The voltage detector 162 is configured for detecting the voltage output by the piezoelectric plate 154 by the electrode plates 152. The memory 164 is configured for storing a predetermined voltage. The controller 166 is configured for determining whether the voltage equals to or exceeds the predetermined voltage, and for controlling the motor 110 accordingly. If the voltage equals to or exceeds the predetermined voltage, the controller 166 deactivates, e.g., powers off, the motor 110 and can reactivate the motor 110 after a predetermined time interval to detect whether the motor 110 is still overloaded. If the motor 110 is still overloaded, the motor 110 is deactivated again. The controller 166 will activate and deactivate the motor 110 repetitiously until the motor 110 is no longer overloaded. Then the motor 110 will remain activated. The predetermined voltage can be determined by the following experiment: initially, the motor 110 is activated by the controller 166 to drive a light load 200 through the first and second rotating portions 130, 140. Then the load 200 is gradually increased until the motor 110 becomes overloaded (stopped). Upon this condition, the output voltage of the piezoelectric assembly 150 is defined as the predetermined voltage.

[0017]Referring to FIG. 5, a protection method for protecting a motor according to a second exemplary embodiment includes steps S202 through S208. Step S202: detecting a voltage output by a piezoelectric assembly. Step S204: determining whether the detected voltage equals to or exceeds a predetermined voltage. If the detected voltage is less than the predetermined voltage, return to step S202. If the detected voltage is equal to or exceeds the predetermined voltage, go to step S206. Step S206: deactivating a motor if the detected voltage equals to or exceeds the predetermined voltage. Step S208: reactivating the motor after a predetermined time and going back to step S202. If the detected voltage equals to or exceeds the predetermined voltage, the motor is deactivated and the process is repeated. The protection method can be carried out by the driving device 100 of the above embodiment.

[0018]The driving device 100 can deactivate the motor 110 if the motor 110 is overloaded. Therefore, the driving device 100 can provide protection for the motor 110.

[0019]It is to be understood, however, that even though numerous characteristics and advantages of the present embodiments have been set fourth in the foregoing description, together with details of the structures and functions of the embodiments, the disclosure is illustrative only, and changes may be made in details, especially in matters of shape, size, and arrangement of parts within the principles of the invention to the full extent indicated by the broad general meaning of the terms in which the appended claims are expressed.

Claims:

1. A driving device comprising:a motor comprising a rotating shaft;a

clutch gear fixed to the rotating shaft;a first rotating portion sleeved

on the rotating shaft corresponding to the clutch gear, the first

rotating portion comprising a first end meshing with the clutch gear and

a second end opposite to the first end;a second rotating portion engaged

with the second end of the first rotating portion;a piezoelectric

assembly sandwiched between the second end of the first rotating portion

and the second rotating portion so that the piezoelectric assembly is

capable of sensing an axial force applied to the second rotating portion

by the first rotating portion, the piezoelectric assembly being capable

of converting the axial force into a voltage; anda controlling unit

electrically connected to the motor and the piezoelectric assembly, the

controlling unit configured for storing a predetermined voltage, and for

determining whether the voltage output by the piezoelectric assembly

equals to or exceeds the predetermined voltage and for deactivating the

motor if the voltage output by the piezoelectric assembly equals to or

exceeds the predetermined voltage.

2. The driving device as claimed in claim 1, wherein the first end is a cylinder, and a plurality of teeth are formed in the first end to mesh with the clutch gear.

3. The driving device as claimed in claim 1, wherein the shape of the second end is approximately a regular-hexagonal-prism, the second end comprises an outer bottom surface, a receiving cavity is defined in the second rotating portion corresponding to the first rotating portion, the second rotating portion comprises an inner bottom surface in the receiving cavity, and the piezoelectric assembly is sandwiched between the outer bottom surface and the inner bottom surface.

4. The driving device of claim 1, wherein the piezoelectric assembly comprises two electrode plates and a piezoelectric plate sandwiched between the two electrode plates.

5. The driving device of claim 1, wherein the controlling unit comprises a voltage detector configured for detecting the voltage output by the piezoelectric assembly, a memory configured for storing the predetermined voltage and a controller configured for determining whether the detected voltage equals to or exceeds the predetermined voltage and deactivating the motor if the detected voltage equals to or exceeds the predetermined voltage.

6. A protection method for a driving device, the driving device comprising a motor comprising a rotating shaft, a clutch gear fixed to the rotating shaft, a first rotating portion sleeved on the rotating shaft, a second rotating portion engaged with the first rotating portion and a piezoelectric assembly sandwiched between the first rotating portion and the second rotating portion so that the piezoelectric assembly is capable of sensing the axial force applied to the second rotating portion by the first rotating portion, the piezoelectric assembly being capable of converting the axial force into a voltage, the method comprising:detecting the voltage output by the piezoelectric assembly;determining whether the detected voltage equals to or exceeds a predetermined voltage; anddeactivating the motor if the detected voltage equals to or exceeds the predetermined voltage.

7. The protection method of claim 6, further comprising repeating the step of detecting the voltage output by the piezoelectric assembly if the detected voltage is lower than the predetermined voltage.

8. The protection method of claim 6, further comprising reactivating the motor after a predetermined time and repeating the step of detecting the voltage output by the piezoelectric assembly.

Description:

BACKGROUND

[0001]1. Technical Field

[0002]The present disclosure relates to driving technology and, particularly, to a driving device and a protection method thereof.

[0003]2. Description of Related Art

[0004]Motors are found in many appliances. In these appliances, it is not uncommon that the load on these motors suddenly increases and goes beyond the power rating of the motors. In these cases, the motors are overloaded while still powered on, and the motors can be damaged under this condition.

[0005]Therefore, what is needed is to provide a driving device and a protection method thereof, in which the above-mention problem is eliminated or at least alleviated.

BRIEF DESCRIPTION OF THE DRAWINGS

[0006]FIG. 1 is a schematic isometric view of a driving device including a controlling unit, according to a first exemplary embodiment.

[0007]FIG. 2 is an exploded schematic isometric view of the driving device of FIG. 1.

[0008]FIG. 3 is a partial exploded schematic isometric view of the driving device of FIG. 1, but viewed from another angle.

[0009]FIG. 4 is a functional block diagram of the controlling unit of FIG. 1.

[0010]FIG. 5 is a flowchart of a protection method, according to a second exemplary embodiment.

DETAILED DESCRIPTION

[0011]Referring to FIGS. 1-3, a driving device 100, according to a first exemplary embodiment, includes a motor 110, a clutch gear 120, a first rotating portion 130, a second rotating portion 140, a piezoelectric assembly 150, and a controlling unit 160. The motor 110 includes a rotating shaft 112, which rotates when the motor 110 is powered on. The clutch gear 120 is fixed to the rotating shaft 112 and rotates with the rotating shaft 112. A number of teeth 122 (FIG. 3) are formed in one side of the clutch gear 120.

[0012]The first rotating portion 130 is hollow and sleeved on the rotating shaft 112. The first rotating portion 130 includes a first end 132 and a second end 134. The first end 132 is a cylinder. A number of teeth 136 are formed in an end surface of the first end 132 to mesh with the number of teeth 122 of the clutch gear 120. The first rotating portion 130 is rotated following the rotation of the clutch gear 120 and is pressed by an axial force from the clutch gear 120 to move toward the second rotating portion 140. The shape of the second end 134 is approximately a regular-hexagonal-prism. The second end 134 includes an outer bottom surface 134a and six outer side surfaces 134b.

[0013]The second rotating portion 140 is a hollow cylinder, and coupled to a load 200. A receiving cavity 142 is defined in the second rotating portion 140, corresponding to the first rotating portion 130. The shape of the receiving cavity 142 is approximately a regular-hexagonal-prism corresponding to the first rotating portion 130 so that the second rotating portion 140 can engagingly mate with the first rotating portion 130 and be driven by the first rotating portion 130 to rotate. The receiving cavity 142 is bounded by an inner bottom surface 143 and six inner side surfaces 144 of the second rotating portion 140. The inner bottom surface 143 corresponds to the outer bottom surface 134a. The six inner side surfaces 144 correspond to the six outer side surfaces 134b, respectively.

[0014]The piezoelectric assembly 150 is sandwiched between the outer bottom surface 134a and the inner bottom surface 143. The piezoelectric assembly 150 is capable of sensing the axial force applied to the second rotating portion 140 by the first rotating portion 130 and the piezoelectric assembly 150 is capable of converting the axial force into a voltage. In this embodiment, the piezoelectric assembly 150 includes two electrode plates 152 and a piezoelectric plate 154 sandwiched between the two electrode plates 152. When the second rotating portion 140 is rotated by the first rotating portion 130, the first rotating portion 130 is pressed by the clutch gear 120 to apply the axial force on the second rotating portion 140, as a result, the piezoelectric plate 154 becomes deformed and outputs the voltage indicative of the intensity of the axial force by the two electrode plates 152.

[0015]The controlling unit 160 is electrically connected to the two electrode plates 152 and the motor 110. Referring to FIG. 4 together with FIG. 2, the controlling unit 160 includes a voltage detector 162, a memory 164, and a controller 166.

[0016]The voltage detector 162 is configured for detecting the voltage output by the piezoelectric plate 154 by the electrode plates 152. The memory 164 is configured for storing a predetermined voltage. The controller 166 is configured for determining whether the voltage equals to or exceeds the predetermined voltage, and for controlling the motor 110 accordingly. If the voltage equals to or exceeds the predetermined voltage, the controller 166 deactivates, e.g., powers off, the motor 110 and can reactivate the motor 110 after a predetermined time interval to detect whether the motor 110 is still overloaded. If the motor 110 is still overloaded, the motor 110 is deactivated again. The controller 166 will activate and deactivate the motor 110 repetitiously until the motor 110 is no longer overloaded. Then the motor 110 will remain activated. The predetermined voltage can be determined by the following experiment: initially, the motor 110 is activated by the controller 166 to drive a light load 200 through the first and second rotating portions 130, 140. Then the load 200 is gradually increased until the motor 110 becomes overloaded (stopped). Upon this condition, the output voltage of the piezoelectric assembly 150 is defined as the predetermined voltage.

[0017]Referring to FIG. 5, a protection method for protecting a motor according to a second exemplary embodiment includes steps S202 through S208. Step S202: detecting a voltage output by a piezoelectric assembly. Step S204: determining whether the detected voltage equals to or exceeds a predetermined voltage. If the detected voltage is less than the predetermined voltage, return to step S202. If the detected voltage is equal to or exceeds the predetermined voltage, go to step S206. Step S206: deactivating a motor if the detected voltage equals to or exceeds the predetermined voltage. Step S208: reactivating the motor after a predetermined time and going back to step S202. If the detected voltage equals to or exceeds the predetermined voltage, the motor is deactivated and the process is repeated. The protection method can be carried out by the driving device 100 of the above embodiment.

[0018]The driving device 100 can deactivate the motor 110 if the motor 110 is overloaded. Therefore, the driving device 100 can provide protection for the motor 110.

[0019]It is to be understood, however, that even though numerous characteristics and advantages of the present embodiments have been set fourth in the foregoing description, together with details of the structures and functions of the embodiments, the disclosure is illustrative only, and changes may be made in details, especially in matters of shape, size, and arrangement of parts within the principles of the invention to the full extent indicated by the broad general meaning of the terms in which the appended claims are expressed.

User Contributions:

Comment about this patent or add new information about this topic:

| People who visited this patent also read: | |

| Patent application number | Title |

|---|---|

| 20140213197 | SIGNAL DETECTION USING A WIDE/NARROW-BAND RF TRANSCEIVER |

| 20140213196 | RECALIBRATION OF ENVELOPE TRACKING TRANSFER FUNCTION DURING ACTIVE TRANSMISSION |

| 20140213195 | APPARATUS AND METHOD FOR ANALYZING EFFECT ON WIRELESS COMMUNICATION SYSTEM BY SOLAR COSMIC RADIO WAVE |

| 20140213194 | MINIMIZATION OF DRIVE-TESTS CONTROL METHOD, SYSTEM, AND NETWORK ELEMENT DEVICE |

| 20140213193 | FREQUENCY OFFSET COMPENSATION FOR WIFI RANGING |