Patent application title: CENTRIFUGAL ELECTRIC PUMP FOR SUCTION OF AERIFORM FLUIDS WITH LIQUIDS ANTI-INFILTRATION DEVICE

Inventors:

Alfonso Bergamaschini (Romanengo, IT)

Assignees:

EMB S.R.L.

IPC8 Class: AF04D1306FI

USPC Class:

41742311

Class name: Electric or magnetic motor rotary motor and rotary nonexpansible chamber pump having means to prevent fluid leaking between pump and motor

Publication date: 2013-11-14

Patent application number: 20130302189

Abstract:

A centrifugal electric pump (1) for suction of aeriform fluids with

liquids anti-infiltration device, including: an electric motor (2)

equipped with a shaft (3); a cylindrical suction box (4) associated with

the motor (2), provided with an intake (5) for aeriform fluid, with at

least one exhaust port (6) and with a closing cover (7) also arranged for

acting as base for the motor (2); at least one fan (8), fitted onto the

shaft (3) and driven in movement by the motor (2); a bearing (9)

interposed between the shaft and the base of the suction box; a liquids

anti-infiltration device (10) arranged between the electric motor (2) and

the suction box (4), provided with a gasket (11), wherein the gasket (11)

rotates with the drive shaft (3) and includes a cylindrical main body

(13) associated with the shaft, and a truncated-cone shaped sealing lip

that cooperates with the flat face of a metal ring (12), provided between

the bearing and the cover (7) of the suction box (4) to produce

watertight closure of the box.Claims:

1) A centrifugal electric pump (1) for suction of aeriform fluids

provided with liquids anti-infiltration device, comprising: an electric

motor (2) equipped with a shaft (3); a cylindrical suction box (4)

associated with said motor (2), provided with an intake (5) for aeriform

fluid positioned centrally with respect to a base (4') of said box, at

least one exhaust port (6) arranged on the lateral surface (4'') thereof

and with a closing cover (7) also arranged for acting as base for said

motor (2); at least one fan (8), fitted onto said shaft (3) and driven in

movement by said motor (2), arranged for sucking a flow of air (F) from

said intake (5), spin it and discharge it outside said suction box (4)

through said at least one exhaust port (6), a bearing (9) interposed

between said shaft and said base of said suction box; a liquids

anti-infiltration device (10), arranged between said electric motor (2)

and said suction box (4), provided with a gasket (11), characterized in

that said gasket (11) rotates with said drive shaft (3) and comprises a

cylindrical main body (13) associated with said shaft, and a

truncated-cone shaped sealing lip (14) that cooperates with a flat face

of a metal ring (12), provided between the bearing and the cover (7) of

said suction box (4) to produce watertight closure of said box.

2) A centrifugal electric pump (1) according to claim 1, characterized in that said gasket (11) is of the V-Ring type with elastic body (13) and sealing lip (14).

3) A centrifugal electric pump (1) according to claim 1, characterized in that a spacer (15) is interposed between said motor shaft (3) and said gasket (11).

Description:

[0001] The present invention relates to the field of fluid machines for

aeriform fluid.

[0002] In particular, the present invention relates to a liquids anti-infiltration device for single or multistage centrifugal pumps and suction fans operated by an electric motor, particularly suitable for use as vacuum pumps in vacuum cleaners and floor washers, for cleaning surfaces through suction of air containing dust, foams or liquids, used in domestic and in industrial and professional environments.

[0003] Centrifugal electric pumps for suction of aeriform fluids of conventional type essentially comprise an electric motor with high number of revolutions and a cylindrical suction box provided with an intake for suction of the fluid and with at least one exhaust port for discharge of said fluid. Movement of the fluid in the inner chamber of said box is caused by at least one impeller, or fan, contained therein, fitted onto the shaft of said electric motor.

[0004] A ball bearing, inserted in an annular cavity, is interposed at the coupling between the cover of said suction box and the main shaft of the electric motor, to enable rotation of the shaft and of the components fixed thereon.

[0005] A similar pump is normally used in vacuum cleaners or floor washers to create a vacuum in a collection tank in which the dust or the liquid contained in the flow of air drawn up is deposited.

[0006] These centrifugal electric pumps for aeriform fluids have a serious drawback: during use, owing to the operating pressures and to the pressure differential created between the suction box and the motor area, due to the geometry of the components and the dimensional tolerances in play, leakages of liquid toward the area occupied by the motor can occur in proximity of the coupling bearing of the drive shaft in the suction box.

[0007] Liquids, or even only foam or moisture in the air drawn up, can damage the ball bearing that supports the drive shaft, causing oxidation, premature wear, decreased efficiency and increased noise thereof.

[0008] Disadvantageously, various operations become necessary to carry out maintenance and to replace parts, with the related additional costs.

[0009] A solution to this problem is disclosed in U.S. Pat. No. 6,472,786, which describes a liquids sealing device for a centrifugal electric pump, arranged for preventing the migration of moisture along the shaft toward the motor.

[0010] Said sealing device is obtained by a ring shaped gasket arranged in the annular cavity around the shaft and adapted to be deformed by compression, due to the force exerted by the cover of the suction box on a metal washer associated with the bearing.

[0011] Said gasket is fixed to said cover and the drive shaft rotates by sliding thereon.

[0012] The seal to close the space that is obtained between the shaft, the bearing and the metal washer is guaranteed by the contact between the internal rim of said ring shaped gasket and said shaft.

[0013] Disadvantageously, the point of contact and closure is very small, almost a simple rest and therefore performances are poor and deteriorate rapidly with wear of the gasket.

[0014] Even more disadvantageously, the deformability of the ring shaped gasket must be well calculated and calibrated exactly on the basis of the space that it must occupy during its compression: the design and choice of each single gasket becomes a precise and delicate operation and does not facilitate the reproducibility of the electric pumps in series.

[0015] As the ring shaped gasket becomes worn, the seal decreases and no type of compensation takes place, thus making it necessary to take action to replace the part, with the related additional costs and time losses.

[0016] The surface on which the gasket acts by rubbing, i.e. the outer surface of the drive shaft, must be suitably treated to obtain particular reductions in the roughness values. This is somewhat complicated and onerous to produce on curved surfaces.

[0017] The aim of the invention is to overcome these limits, by producing a centrifugal electric pump for suction of aeriform fluids provided with a liquids anti-infiltration device to protect the drive shaft support bearing.

[0018] A further aim of the invention is to produce an anti-filtration device that is highly reliable, easy to mount, adaptable to any drive shaft and tolerance between components, with increased durability, which prevents or reduces accessory fixing means and limits the costs for manufacturing and surface treatment of the metal sealing components.

[0019] These aims are achieved with a centrifugal electric pump for suction of aeriform fluids with liquids anti-infiltration device, comprising:

[0020] an electric motor equipped with a shaft;

[0021] a cylindrical suction box associated with said motor, provided with an intake for aeriform fluid positioned centrally with respect to a base of said box, at least one exhaust port arranged on the lateral surface thereof and with a closing cover also arranged for acting as base for said motor;

[0022] at least one fan, fitted onto said shaft and driven in movement by said motor, arranged for sucking a flow of air from said intake, spin it and discharge it outside said suction box through said at least one exhaust port;

[0023] a bearing interposed between said shaft and said base of said suction box;

[0024] a liquids anti-infiltration device, arranged between said electric motor and said suction box, provided with a gasket, characterized in that said gasket rotates with said drive shaft and comprises a cylindrical main body associated with said shaft, and a truncated-cone shaped sealing lip that cooperates with a flat face of a metal ring, provided between the bearing and the cover of said suction box to produce watertight closure of said box.

[0025] In particular, said gasket is of the V-Ring type, with elastic body and sealing lip.

[0026] According to one embodiment of the invention, a spacer is interposed between said drive shaft and said gasket.

[0027] The advantages of the invention are as follows.

[0028] The main advantage consists in the excellent liquid seal produced between the suction box of said centrifugal electric pump and its electric motor, due to the shape and to the type of gasket used, and to the relative method of positioning thereof.

[0029] In fact, the gasket operates in an optimal manner, with sliding friction on an abutment surface perpendicular to the axis of said shaft, constituted by the flat face of a metal adapter ring.

[0030] A further advantage consists in the fact that the surface of the flat face of said metal ring can be easily subjected to honing treatments, without excessive increases in costs, obtaining an improved seal between the gasket and said ring, reduced wear of the lip of the gasket and increased durability of the device.

[0031] The metal ring therefore makes it possible to use suitable materials and surface treatments suitable to optimize cooperation with the sealing lip of the gasket.

[0032] Moreover, the choice of a given thickness of metal ring enables the distance between the gasket and the sliding sealing surface to be appropriately compensated.

[0033] The gasket used also has the following advantages:

[0034] it is extremely easy to mount, the operation can be carried out with or without the aid of a simple tool, enlarging the inner diameter of the cylindrical ring shaped body to be fitted onto the shaft;

[0035] it has low friction and therefore generates very low load losses;

[0036] it can also operate dry;

[0037] due to the elastic nature, it does not require the contact surfaces to have particularly high roughness values;

[0038] it does not cause any wear on the drive shaft and does not require particular tolerances and roughness values for this;

[0039] a single gasket can be easily adapted to different diameters of drive shaft.

[0040] The anti-infiltration device according to the invention, due to cooperation between the components, to their positioning and to the configuration of the gasket, ensure a perfect seal even in the case of partial wear of said gasket: progressive wear of the sealing lip is compensated through the external pressure generated in the suction box which is exerted on said gasket, which in any case defines its contact on the flat face of the metal abutment ring.

[0041] Even more advantageously, the total absence of leakages of liquids toward the bearing protects this latter from possible wear and damage, preventing rusting which can lead to noisy operation.

[0042] A further advantage consists in the simplicity with which said gasket is maintained in position solely through the operating pressure inside the electric pump, without the addition of fixing components and particular clamping systems.

[0043] These and other advantages will be more evident hereinbelow, in the description of a preferred embodiment, provided by way of an indicative and non-limiting example, and with the aid of the figures wherein:

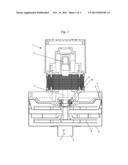

[0044] FIGS. 1 and 4 represent, respectively in cross section and in a sectional axonometric view, a centrifugal pump for suction of aeriform fluids provided with a liquids anti-infiltration device according to the invention;

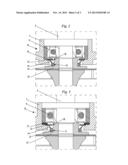

[0045] FIG. 2 represents, in cross section, a detail of the pump of FIG. 1;

[0046] FIG. 3 represents, in cross section, un detail of the pump according to a possible embodiment of the invention.

[0047] With reference to FIGS. 1, 2 and 4, there is shown a centrifugal electric pump for suction of aeriform fluids provided with a liquids anti-infiltration device according to a preferred embodiment of the invention.

[0048] Said electric pump 1 is essentially constituted by an electric motor 2 provided with a drive shaft 3, by a suction box 4 and by fans 8 arranged for driving a flow of air F.

[0049] Said suction box 4 has a cylindrical shape, comprises a circular bottom provided with a suction inlet 5 arranged centrally and a lateral surface provided with at least one exhaust port 6, and is associated with said shaft 3 with a bearing 9 interposed.

[0050] Said box 4 is closed at the top by a cover 7 adapted also to act as base for said motor 2.

[0051] Said fans 8 are fitted onto said drive shaft 3 and are driven in movement by said motor 2.

[0052] An annular cavity 18 arranged for housing said bearing 9 is produced between said motor shaft 3 and said cover 7.

[0053] The anti-filtration device 10 according to the invention is positioned in said annular cavity 18.

[0054] With particular reference to FIG. 2, the liquids anti-infiltration device 10 comprises a gasket 11 and a metal ring 12.

[0055] Said gasket 11 comprises a cylindrical ring shaped main body 13, with inner diameter suitable to be fitted onto said shaft 3, and a truncated-cone shaped sealing lip 14.

[0056] The gasket 11 is of the V-Ring type, with elastic body 13 and sealing lip 14.

[0057] Said gasket 11 is arranged coaxially on said drive shaft 3 and rotates therewith, if necessary with a closing spacer 15 interposed, while a metal ring 12, arranged for acting as abutment surface for sliding of the sealing lip 14 of said gasket 11, is associated on the cover 7 of said suction box.

[0058] Gaskets of this type are normally made of nitrile rubber.

[0059] A rubber reducer 16, with the function of adapting the seat of the annular cavity 18 and retaining the bearing 9, is interposed between said metal ring 12, the cover 7 and the bearing 9.

[0060] With reference to FIG. 3, said rubber reducer 16 is replaced equivalently with a wave washer 17.

[0061] The operating methods of the anti-infiltration device are as follows.

[0062] The V-Ring gasket is mounted on the motor shaft 3 and rotates therewith. The main body 13 is mounted with interference on the shaft 3 and maintains the lip 14 in position. In particular, the lip 14 produces the liquid seal against the abutment surface of the metal ring 12, arranged perpendicularly to the shaft 3.

[0063] In use, the elasticity of the sealing lip 14 and the high pressure inside the suction box 4 help to maintain the spacer 15 pressed against the cover 7, also compressing the gasket 11. The lip 14 is deformed, increasing the surface area thereof that rests on the metal ring 12 and thus preventing any liquids from leaking inside the motor 2.

User Contributions:

Comment about this patent or add new information about this topic:

| People who visited this patent also read: | |

| Patent application number | Title |

|---|---|

| 20210035385 | VEHICLE SYSTEM AND VEHICLE |

| 20210035384 | METHODS AND SYSTEMS FOR DETERMINING A DRIVER PENALTY SCORE BASED ON HARSH DRIVING EVENTS |

| 20210035383 | SYSTEM FOR MANAGEMENT OF VERIFICATION OF PROJECT COMMENCEMENT AND COMPLETION |

| 20210035382 | VEHICLE IDLE NOTIFICATION SYSTEM AND METHOD |

| 20210035381 | METHOD AND APPARATUS FOR PROCESSING DIAGNOSIS DATA, DIAGNOSIS DEVICE AND SERVER |