Patent application title: Device for Measuring the Metal Level in a Reduction Basin

Inventors:

Peter Palsson (Stockholm, SE)

IPC8 Class: AC25C314FI

USPC Class:

2042281

Class name: Apparatus electrolytic with current, voltage, or power control means responsive to sensed condition

Publication date: 2011-03-31

Patent application number: 20110073466

an arrangement for producing aluminium,

comprising a cathodic vessel, anode means, an electricity source for

generating a direct current between the cathodic vessel and the anode

means in order to obtain molten aluminium from a bath, and a subassembly

for breaking a crust formed in the area of the anode means during the

production. Said subassembly encompasses a chisel which is operated by

means of a pneumatic cylinder comprising a sensor for sensing the lift of

a piston rod of the cylinder and is electrically connected to a terminal

of an electronic unit. Another terminal of the electronic unit is

connected to the cathodic vessel in order to generate an alternating

current between the chisel and the cathodic vessel and measure the

potential and/or the alternating current there-between. The chisel has

means for forming an electrode in the bottom zone as well as electronic

connecting means for connecting the electrode to one terminal of the

electronic unit.Claims:

1. Device for production of aluminium including a cathodic pot, anode

means, an electric source for creating an DC-current between the cathodic

pot and the anode means for extraction of molten aluminium out of a bath,

and an assembly for breaking open a crust, which is formed during the

production in the area of the anode means, with a chisel driven by a

pneumatic cylinder having a sensor for detecting the stroke of a piston

rod of the cylinder and is electrical connected to one terminal of an

electronic unit, while another terminal of the electronic unit is

connected to the cathodic pot for creating an AC-current between chisel

and the cathodic pot and measuring the potential and/or AC-current

between both, wherein; the chisel comprises means for forming an

electrode in the bottom part and electrical connection means for

connecting the electrode to the one terminal of the electronic unit.

2. Device according to claim 1, wherein; the electrical connection means are arranged inside a hollow along the middle axis of the chisel and that the top cover of the chisel is electrically insulated thereto.

3. Device according to claim 2, wherein; the electrical connection means are formed by an electrical cable.

4. Device according to claim 2, wherein; the electrical connection means are formed by a chisel rod, which is arranged in the hollow of the chisel and serves as a mechanical fasten element for the chisel tube and the top cover of the chisel.

5. Device according to one of the claim 2, wherein; the chisel consists of electronic insulating material.

6. Device according to claim 1, wherein; the sidewalls of the chisel are electronically insulated.

7. Device according to claim 1, wherein; chisel is connected to the piston rod via a mechanical coupling part, which consists of an electrically leading material.

8. Device according to claim 1, wherein; the insulation material is of an ceramic material.

9. Device according to claim 1, wherein; the sensor is a resistive sensor.Description:

FIELD OF THE INVENTION

[0001]The invention is related to a device for production of aluminium including a cathodic pot, anode means, an electric source for creating an DC-current between the cathodic pot and the anode means for extraction of molten aluminium out of a bath, and an assembly for breaking open a crust, which is formed during the production in the area of the anode means, with a chisel driven by a pneumatic cylinder having a sensor for detecting the stroke of a piston rod of the cylinder and is electrical connected to one terminal of an electronic unit, while another terminal of the electronic unit is connected to the cathodic pot for creating an AC-current between chisel and the cathodic pot and measuring the potential and/or the AC-current between both.

BACKGROUND OF THE INVENTION

[0002]The very important resource aluminium is nowadays gained by methods like a Hall/Heroult cell. During this method aluminium is extracted out of a bath by creating an electric current between a cathodic pot, which contains the bath, and an anode. Thus a layer of molten aluminium is created on the bottom of the cathodic pot and is extracted by suction, while the oxygen formed during the electrolysis reacts with carbon of the anode to carbon dioxide. Furthermore a crust, which covers the bath, is formed in the area of the anode. This crust has to be broken up to supply further aluminium oxide to the cathodic pot during the production of aluminium.

STATE OF THE ART

[0003]WO 01/06039 discloses such a device for production of aluminium by a Hall/Heroult cell, which includes a cathodic pot, anode means and an electric source for creating an electric current between the pot and the anode. Furthermore an assembly is arranged containing a pneumatic cylinder with a chisel, which is electronically connected by an electronic unit with the pot, for breaking open a crust, which is formed during the process of production of aluminium in the area of the anode. The pneumatic cylinder and thus the movement of the chisel are controlled by the electronic connection of the chisel with the pot so that a thermal stress of the chisel during breaking open the crust and dipping into the melt is minimized.

[0004]U.S. Pat. No. 4,857,157 discloses a method for controlling the addition of the aluminium oxide to the Hall/Heroult cell by measuring the level of bath and melt in the pot. Therefore the rise of a chisel of an assembly for braking open the crust is detected by an electric contact and a resistor. When the chisel then gets in contact with the bath the potential of the resistor rises suddenly and the current rise of the chisel is noted. With a estimated height of the layer of molten aluminium it is thus possible to calculate the height of bath.

[0005]The disadvantage of the known state of art is, that the level of the layer of molten aluminium can only be estimated, not measured. Because of leakage currents from the bath the electrical potential in top of the chisel is higher than at the bottom. Since the electrical potential is measured in top of the chisel, this causes measurement inaccuracy. Another problem is that the voltage from the electrical source is fluctuating.

OBJECT OF THE INVENTION

[0006]It is therefore the task of the invention to provide a device for measuring the level of the layer of molten aluminium with a high accuracy.

[0007]This object is achieved by the chisel comprising means for creating an electrode in the bottom part and electrical connection means for connecting the electrode to one terminal of an electronic unit. Thus it is possible to measure the level of the layer of molten aluminium in the pot since the point of measuring is moved to the bottom part of the chisel and leakage currents don't have an effect on the measurement.

[0008]According to a preferred embodiment of the invention the electrical connection means are arranged inside a hollow along the middle axis of the chisel and the top cover of the chisel is electrically insulated thereto. Thus the chisel can be made of conventional material while a accurate measurement is guaranteed.

[0009]According to a further embodiment of the invention the electrical connection means are formed by an electrical cable. This implicates the advantage, that a low-cost connection to the one terminal of the electronic unit can be achieved.

[0010]According to a further preferred embodiment of the invention the electrical connection means are formed by a chisel rod, which is arranged in the hollow of the chisel and serves as a mechanical fasten element for the chisel tube and the cover of the chisel. Thereby it is possible to achieve a tough version of the chisel.

[0011]According to a further embodiment the chisel consists of an electronic insulating material. The advantage is, that such a chisel is only conductive on the desired surfaces.

[0012]According to another embodiment of the invention the sidewalls of the chisel are electronically insulated. This implicates the advantage, that leakage currents can be avoided with a small effort, because a conventional chisel can be used in combination with an insulating coating.

[0013]According to another embodiment the chisel is connected to the piston rod via a mechanical connection, which is of an electrically leading material. By using this method a connection of the chisel to the electronic unit can be realized with a small effort, since it can be done via the pneumatic cylinder.

[0014]According to a further embodiment the insulation material is of an ceramic material. Therefore a reliable insulation is realized.

[0015]According to another preferred embodiment the sensor is a resistive sensor. The advantage is, that the stroke of the piston rod of the pneumatic cylinder and thereby the stroke of the chisel can be noted accurately and with a low effort.

BRIEF DESCRIPTION OF THE DRAWINGS

[0016]The invention will now be described in more detail at the background of embodiments and with reference to the drawings, wherein:

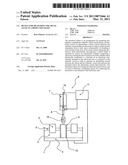

[0017]FIG. 1 diagrammatically shows the device for production of aluminium according to a first embodiment of the invention,

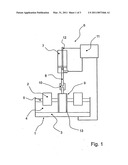

[0018]FIG. 2 diagrammatically shows the device for production of aluminium according to a second embodiment of the invention, and

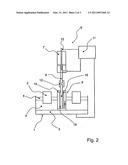

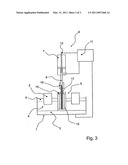

[0019]FIG. 3 diagrammatically shows the device for production of aluminium according to a third embodiment of the invention.

DETAILED DESCRIPTION OF THE DRAWINGS

[0020]In FIG. 1 the device for production of aluminium according to the invention is shown, which comprises a cathodic pot 1 and anode means 2, being connected by a--not shown--electric source. This electric source creates a electric current between the cathodic pot 1 and the anode means 2 to cause the effect of a Hall/Heroult cell in an bath 4, in which aluminium exists in a compound. Thereby a layer of pure aluminium 3 accumulates in the bottom area of the cathodic pot 1, while a layer of crust 5 covers the bath 4 close to the anode means 2. For breaking open this crust 5 an assembly 6 is arranged near the cathodic pot 1. This assembly 6 comprises a pneumatic cylinder 7 with a piston rod 8, which is mechanically connected to a chisel 9 via a mechanical coupling part 10 of an electrical leading material. The chisel 9 is furthermore via the mechanical coupling part 10 and the piston rod 8 electronically connected to a electronic unit 11, while another terminal of the electronic unit 11 is wired with the cathodic pot 1. In the upper part of the pneumatic cylinder 7 moreover a linear sensor 12 is placed, for detecting the stroke of the piston rod 8 and chisel 9. To avoid leakage currents through the sidewalls of the chisel 9 a coating of an insulating material 13 is provided.

[0021]During the production of pure aluminium 3 out of a bath 4 by a Hall/Heroult cell the emerging crust 5 is broken open by the chisel 9. The stroke of the chisel 9 moved by the pneumatic cylinder 7 is controlled by the electronic unit 11. Therefore a relative low voltage is impressed at the chisel 9 and depending on the electric current measured at the terminal of the electronic unit 11 connected to the cathodic pot 1 the chisel 9 is moved downward and as the case may be pulled back. In the area of the crust 5 the conductivity is very low, while in the layer of the bath 4 it is higher, getting it's maximum in the layer of pure aluminium 3, where the chisel 9 has to be pulled back fast because of the very high temperature. Since the linear sensor notes the stroke of the piston rod 8 and the chisel 9, in combination with the measured electronic currents by the electronic unit 11 the levels of the different layers can be measured.

[0022]By contrast in FIG. 2 only the inner and bottom part of the chisel 9 are electronically connected to the electronic unit 11 via a chisel rod 15 in a hollow 16 of the chisel 9, while between the side walls of the chisel 9 and the chisel rod 15 is an air gap. The leakage currents between the side walls and the bottom part of the chisel 9 are indicated by a resistance. Furthermore the top cover 14 between the chisel 9 and the connection means is of an insulating material.

[0023]In FIG. 3 the chisel 9 is fully made of insulating material 13, while the electronic connection to the electronic unit 11 is realized by a cable 17, which runs in the inner part of chisel 9. Again the top cover 14 of the chisel 9 is of an insulating material.

Claims:

1. Device for production of aluminium including a cathodic pot, anode

means, an electric source for creating an DC-current between the cathodic

pot and the anode means for extraction of molten aluminium out of a bath,

and an assembly for breaking open a crust, which is formed during the

production in the area of the anode means, with a chisel driven by a

pneumatic cylinder having a sensor for detecting the stroke of a piston

rod of the cylinder and is electrical connected to one terminal of an

electronic unit, while another terminal of the electronic unit is

connected to the cathodic pot for creating an AC-current between chisel

and the cathodic pot and measuring the potential and/or AC-current

between both, wherein; the chisel comprises means for forming an

electrode in the bottom part and electrical connection means for

connecting the electrode to the one terminal of the electronic unit.

2. Device according to claim 1, wherein; the electrical connection means are arranged inside a hollow along the middle axis of the chisel and that the top cover of the chisel is electrically insulated thereto.

3. Device according to claim 2, wherein; the electrical connection means are formed by an electrical cable.

4. Device according to claim 2, wherein; the electrical connection means are formed by a chisel rod, which is arranged in the hollow of the chisel and serves as a mechanical fasten element for the chisel tube and the top cover of the chisel.

5. Device according to one of the claim 2, wherein; the chisel consists of electronic insulating material.

6. Device according to claim 1, wherein; the sidewalls of the chisel are electronically insulated.

7. Device according to claim 1, wherein; chisel is connected to the piston rod via a mechanical coupling part, which consists of an electrically leading material.

8. Device according to claim 1, wherein; the insulation material is of an ceramic material.

9. Device according to claim 1, wherein; the sensor is a resistive sensor.

Description:

FIELD OF THE INVENTION

[0001]The invention is related to a device for production of aluminium including a cathodic pot, anode means, an electric source for creating an DC-current between the cathodic pot and the anode means for extraction of molten aluminium out of a bath, and an assembly for breaking open a crust, which is formed during the production in the area of the anode means, with a chisel driven by a pneumatic cylinder having a sensor for detecting the stroke of a piston rod of the cylinder and is electrical connected to one terminal of an electronic unit, while another terminal of the electronic unit is connected to the cathodic pot for creating an AC-current between chisel and the cathodic pot and measuring the potential and/or the AC-current between both.

BACKGROUND OF THE INVENTION

[0002]The very important resource aluminium is nowadays gained by methods like a Hall/Heroult cell. During this method aluminium is extracted out of a bath by creating an electric current between a cathodic pot, which contains the bath, and an anode. Thus a layer of molten aluminium is created on the bottom of the cathodic pot and is extracted by suction, while the oxygen formed during the electrolysis reacts with carbon of the anode to carbon dioxide. Furthermore a crust, which covers the bath, is formed in the area of the anode. This crust has to be broken up to supply further aluminium oxide to the cathodic pot during the production of aluminium.

STATE OF THE ART

[0003]WO 01/06039 discloses such a device for production of aluminium by a Hall/Heroult cell, which includes a cathodic pot, anode means and an electric source for creating an electric current between the pot and the anode. Furthermore an assembly is arranged containing a pneumatic cylinder with a chisel, which is electronically connected by an electronic unit with the pot, for breaking open a crust, which is formed during the process of production of aluminium in the area of the anode. The pneumatic cylinder and thus the movement of the chisel are controlled by the electronic connection of the chisel with the pot so that a thermal stress of the chisel during breaking open the crust and dipping into the melt is minimized.

[0004]U.S. Pat. No. 4,857,157 discloses a method for controlling the addition of the aluminium oxide to the Hall/Heroult cell by measuring the level of bath and melt in the pot. Therefore the rise of a chisel of an assembly for braking open the crust is detected by an electric contact and a resistor. When the chisel then gets in contact with the bath the potential of the resistor rises suddenly and the current rise of the chisel is noted. With a estimated height of the layer of molten aluminium it is thus possible to calculate the height of bath.

[0005]The disadvantage of the known state of art is, that the level of the layer of molten aluminium can only be estimated, not measured. Because of leakage currents from the bath the electrical potential in top of the chisel is higher than at the bottom. Since the electrical potential is measured in top of the chisel, this causes measurement inaccuracy. Another problem is that the voltage from the electrical source is fluctuating.

OBJECT OF THE INVENTION

[0006]It is therefore the task of the invention to provide a device for measuring the level of the layer of molten aluminium with a high accuracy.

[0007]This object is achieved by the chisel comprising means for creating an electrode in the bottom part and electrical connection means for connecting the electrode to one terminal of an electronic unit. Thus it is possible to measure the level of the layer of molten aluminium in the pot since the point of measuring is moved to the bottom part of the chisel and leakage currents don't have an effect on the measurement.

[0008]According to a preferred embodiment of the invention the electrical connection means are arranged inside a hollow along the middle axis of the chisel and the top cover of the chisel is electrically insulated thereto. Thus the chisel can be made of conventional material while a accurate measurement is guaranteed.

[0009]According to a further embodiment of the invention the electrical connection means are formed by an electrical cable. This implicates the advantage, that a low-cost connection to the one terminal of the electronic unit can be achieved.

[0010]According to a further preferred embodiment of the invention the electrical connection means are formed by a chisel rod, which is arranged in the hollow of the chisel and serves as a mechanical fasten element for the chisel tube and the cover of the chisel. Thereby it is possible to achieve a tough version of the chisel.

[0011]According to a further embodiment the chisel consists of an electronic insulating material. The advantage is, that such a chisel is only conductive on the desired surfaces.

[0012]According to another embodiment of the invention the sidewalls of the chisel are electronically insulated. This implicates the advantage, that leakage currents can be avoided with a small effort, because a conventional chisel can be used in combination with an insulating coating.

[0013]According to another embodiment the chisel is connected to the piston rod via a mechanical connection, which is of an electrically leading material. By using this method a connection of the chisel to the electronic unit can be realized with a small effort, since it can be done via the pneumatic cylinder.

[0014]According to a further embodiment the insulation material is of an ceramic material. Therefore a reliable insulation is realized.

[0015]According to another preferred embodiment the sensor is a resistive sensor. The advantage is, that the stroke of the piston rod of the pneumatic cylinder and thereby the stroke of the chisel can be noted accurately and with a low effort.

BRIEF DESCRIPTION OF THE DRAWINGS

[0016]The invention will now be described in more detail at the background of embodiments and with reference to the drawings, wherein:

[0017]FIG. 1 diagrammatically shows the device for production of aluminium according to a first embodiment of the invention,

[0018]FIG. 2 diagrammatically shows the device for production of aluminium according to a second embodiment of the invention, and

[0019]FIG. 3 diagrammatically shows the device for production of aluminium according to a third embodiment of the invention.

DETAILED DESCRIPTION OF THE DRAWINGS

[0020]In FIG. 1 the device for production of aluminium according to the invention is shown, which comprises a cathodic pot 1 and anode means 2, being connected by a--not shown--electric source. This electric source creates a electric current between the cathodic pot 1 and the anode means 2 to cause the effect of a Hall/Heroult cell in an bath 4, in which aluminium exists in a compound. Thereby a layer of pure aluminium 3 accumulates in the bottom area of the cathodic pot 1, while a layer of crust 5 covers the bath 4 close to the anode means 2. For breaking open this crust 5 an assembly 6 is arranged near the cathodic pot 1. This assembly 6 comprises a pneumatic cylinder 7 with a piston rod 8, which is mechanically connected to a chisel 9 via a mechanical coupling part 10 of an electrical leading material. The chisel 9 is furthermore via the mechanical coupling part 10 and the piston rod 8 electronically connected to a electronic unit 11, while another terminal of the electronic unit 11 is wired with the cathodic pot 1. In the upper part of the pneumatic cylinder 7 moreover a linear sensor 12 is placed, for detecting the stroke of the piston rod 8 and chisel 9. To avoid leakage currents through the sidewalls of the chisel 9 a coating of an insulating material 13 is provided.

[0021]During the production of pure aluminium 3 out of a bath 4 by a Hall/Heroult cell the emerging crust 5 is broken open by the chisel 9. The stroke of the chisel 9 moved by the pneumatic cylinder 7 is controlled by the electronic unit 11. Therefore a relative low voltage is impressed at the chisel 9 and depending on the electric current measured at the terminal of the electronic unit 11 connected to the cathodic pot 1 the chisel 9 is moved downward and as the case may be pulled back. In the area of the crust 5 the conductivity is very low, while in the layer of the bath 4 it is higher, getting it's maximum in the layer of pure aluminium 3, where the chisel 9 has to be pulled back fast because of the very high temperature. Since the linear sensor notes the stroke of the piston rod 8 and the chisel 9, in combination with the measured electronic currents by the electronic unit 11 the levels of the different layers can be measured.

[0022]By contrast in FIG. 2 only the inner and bottom part of the chisel 9 are electronically connected to the electronic unit 11 via a chisel rod 15 in a hollow 16 of the chisel 9, while between the side walls of the chisel 9 and the chisel rod 15 is an air gap. The leakage currents between the side walls and the bottom part of the chisel 9 are indicated by a resistance. Furthermore the top cover 14 between the chisel 9 and the connection means is of an insulating material.

[0023]In FIG. 3 the chisel 9 is fully made of insulating material 13, while the electronic connection to the electronic unit 11 is realized by a cable 17, which runs in the inner part of chisel 9. Again the top cover 14 of the chisel 9 is of an insulating material.

User Contributions:

Comment about this patent or add new information about this topic:

| People who visited this patent also read: | |

| Patent application number | Title |

|---|---|

| 20190087884 | THEME RECOMMENDATION METHOD AND APPARATUS |

| 20190087883 | SYSTEMS AND METHODS FOR GENERATING LOCATION-BASED GROUP RECOMMENDATIONS |

| 20190087882 | SYSTEMS, METHODS, AND DEVICES FOR DYNAMIC USED VEHICLE MARKETING, DEALER MATCHING, AND EXTENDED SALE PERIOD TRANSACTIONS PLATFORM |

| 20190087881 | SYSTEM AND METHOD FOR PREDICTIVE QUOTING |

| 20190087880 | SYSTEM FOR REAL TIME AUTOMATED MARKET PROCESSING |