Patent application title: DOWNHOLE TOOL ACTUATING ARRANGEMENT AND METHOD OF RESETTING AT LEAST ONE DOWNHOLE TOOL

Inventors:

IPC8 Class: AE21B3410FI

USPC Class:

166375

Class name: Operating valve, closure, or changeable restrictor in a well operated by fluid pressure controlled above ground by auxilliary fluid control line

Publication date: 2016-06-16

Patent application number: 20160168948

Abstract:

A downhole tool actuating arrangement includes, a control system

configured to communicate pressurized fluid to at least one downhole tool

actuatable by pressure changes in the control system, a check valve in

operable communication with the control system configured to prevent

fluid flow through the check valve in a direction opposite to flow that

causes increases in pressure in the control system, and a bleed device.

The bleed device is in operable communication with the control system

downstream of the check valve, wherein downstream is defined by a

direction of flow that causes the check valve to open. The bleed device

is configured to allow fluid flow therethrough when pressure on the

control system side of the bleed device is greater than on a side

opposite the control system.Claims:

1. A downhole tool actuating arrangement, comprising: a control system

configured to communicate pressurized fluid to at least one downhole tool

actuatable by pressure changes in the control system; a check valve in

operable communication with the control system configured to prevent

fluid flow through the check valve in a direction opposite to flow that

causes increases in pressure in the control system; and a bleed device in

operable communication with the control system downstream of the check

valve, downstream being defined by a direction of flow that causes the

check valve to open, the bleed device being configured to allow fluid

flow therethrough in response to pressure on the control system side of

the bleed device being greater than on a side opposite the control

system.

2. The downhole tool actuating arrangement of claim 1, wherein the bleed device is configured to be fluidically connected to a control system that was previously positioned downhole.

3. The downhole tool actuating arrangement of claim 2, wherein the control system has been functionally operated prior to connection of the bleed device.

4. The downhole tool actuating arrangement of claim 2, wherein the bleed device is configured to be fluidically connected to the control system downstream of the check valve and the check valve was positioned downhole prior to installation of the bleed device.

5. The downhole tool actuating arrangement of claim 1, wherein the bleed device ports fluid exhausted therethrough to an annular space between a tool string and a structure.

6. The downhole tool actuating arrangement of claim 5, wherein the structure is selected from the group consisting of an open hole, a liner and a casing.

7. The downhole tool actuating arrangement of claim 1, wherein the bleed device ports fluid exhausted therethrough to an exhaust line from a multi-cycle device.

8. The downhole tool actuating arrangement of claim 7, wherein the multi-cycle device is a single line switch.

9. The downhole tool actuating arrangement of claim 8, wherein the bleed device provides fluidic communication between an inlet to the bleed device and an exhaust of the single line switch.

10. The downhole tool actuating arrangement of claim 1, wherein the bleed device allows substantially constant flow therethrough regardless of a pressure differential applied thereacross.

11. The downhole tool actuating arrangement of claim 10, wherein the substantially constant flow is in a range of about 35 to 40 ml per minute.

12. The downhole tool actuating arrangement of claim 10, wherein the substantially constant flow continues to flow through the bleed device while tools are actuated by the pressure increases.

13. The downhole tool actuating arrangement of claim 1, wherein the at least one downhole tool is resettable in response to pressure decreases in the control system due to fluid flowing through the bleed device.

14. The downhole tool actuating arrangement of claim 13, wherein flow through the bleed device allows the at least one downhole tool to reset automatically.

15. The downhole tool actuating arrangement of claim 1, further comprising a filter between the control system and the bleed device.

16. A method of resetting at least one downhole tool, comprising: opening a check valve in operable communication with a control system the control system being in operable communication with the at least one downhole tool; increasing pressure in the control system; actuating the at least one downhole tool; decreasing pressure upstream of the check valve; closing the check valve; bleeding fluid from the control system through a bleed device downstream of the check valve; decreasing pressure in the control system downstream of the check valve; and resetting the at least one downhole tool.

17. The method of resetting at least one downhole tool of claim 16, further comprising continuously bleeding fluid through the bleed device.

18. The method of resetting at least one downhole tool of claim 16, further comprising flowing a substantially constant flow through the bleed device.

19. The method of resetting at least one downhole tool of claim 16, further comprising porting fluid bled through the bleed device to an annulus between a tool string and a structure surrounding the tool string.

20. The method of resetting at least one downhole tool of claim 16, further comprising supplying fluid to a multi-cycle device.

21. The method of resetting at least one downhole tool of claim 20, further comprising bleeding fluid through the bleed device upstream of the multi-cycle device to an exhaust line from the multi-cycle device.

Description:

CROSS REFERENCE TO RELATED APPLICATIONS

[0001] This application contains subject matter related to the subject matter of a co-pending application that is assigned to the same assignee as this application, Baker Hughes Incorporated of Houston, Tex. The below listed application is hereby incorporated by reference in its entirety:

[0002] U.S. Patent Application Attorney Docket No. ICN4-57960-US-NP/BA01264US, entitled: CONTROL SYSTEM INCLUDING SINGLE LINE SWITCHES AND METHOD, filed Oct. 27, 2014.

BACKGROUND

[0003] Employing pressure variations via fluid in control lines is a common way to actuate tools in tubular systems such as in earth formation boreholes in the carbon dioxide sequestration and the hydrocarbon recover industries, for example. Systems and methods employing such variations serve the purpose for which they are intended. Those who practice in the art, however, are always receptive to new systems and methods that improve the current state of the art.

BRIEF DESCRIPTION

[0004] Disclosed herein is a downhole tool actuating arrangement. The arrangement includes, a control system configured to communicate pressurized fluid to at least one downhole tool actuatable by pressure changes in the control system, a check valve in operable communication with the control system configured to prevent fluid flow through the check valve in a direction opposite to flow that causes increases in pressure in the control system, and a bleed device. The bleed device is in operable communication with the control system downstream of the check valve, wherein downstream is defined by a direction of flow that causes the check valve to open. The bleed device is configured to allow fluid flow therethrough when pressure on the control system side of the bleed device is greater than on a side opposite the control system.

[0005] Further disclosed herein is a method of resetting at least one downhole tool. The method includes, opening a check valve in operable communication with a control system that is in operable communication with the at least one downhole tool, increasing pressure in the control system, actuating the at least one downhole tool, decreasing pressure upstream of the check valve, closing the check valve, bleeding fluid from the control system through a bleed device downstream of the check valve, decreasing pressure in the control system downstream of the check valve, and resetting the at least one downhole tool.

BRIEF DESCRIPTION OF THE DRAWINGS

[0006] The following descriptions should not be considered limiting in any way. With reference to the accompanying drawings, like elements are numbered alike:

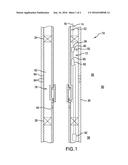

[0007] FIG. 1 depicts a schematic view a downhole tool actuating arrangement disclosed herein; and

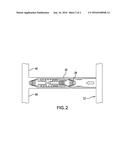

[0008] FIG. 2 depicts a cross sectional view of an embodiment of a bleed device employable in the downhole tool actuating arrangement of FIG. 1.

DETAILED DESCRIPTION

[0009] A detailed description of one or more embodiments of the disclosed apparatus and method are presented herein by way of exemplification and not limitation with reference to the Figures.

[0010] Referring to FIG. 1, an embodiment of a downhole tool actuating arrangement disclosed herein is illustrated at 10. The downhole tool actuating arrangement 10 includes a control system 12 in operable communication with at least one downhole tool 18, with one of the tools 18 being shown while any number of the tools 18 could be employed, such that increases in pressure of fluid within the control system 12 can actuate the tool 18. A check valve 22 is positioned in a control line 14 upstream of the control system 12. The check valve 22 is configured to prevent fluid flow through the check valve 22 in a direction opposite to flow that causes increases in pressure in the control system 12. The check valve 22 can be in the control line 14 directly, as in the illustrated embodiment, or in an alternate line of the control system 12 that is in fluidic communication with the control line 14. A bleed device 26 is in operable communication with the control system 12 and is positioned downstream of the check valve 22; downstream being defined by a direction of flow that causes the check valve 22 to open. The bleed device 26 is configured to allow fluid flow therethrough from the control line 14 as long as pressure is greater on the control system 22 side of the bleed device 26 as best shown in FIG. 2.

[0011] The bleed device 26 may be as simple as a fixed sized orifice through which the fluid is able to flow. In such case the flow through the bleed device 26 will vary with changes in pressure across the bleed device 26. In alternate embodiments the bleed device 26 can be configured to allow a substantially constant flow therethrough independent of pressure across the bleed device 26. Using a Lee Flowsert.TM. flow regulating valve, shown in FIG. 2, made by the Lee Company as the bleed device 26, for example, would fit this embodiment. A Lee Flowsert.TM. having a flow in a range of about 35 to 40 ml per minute over a wide range of pressure drops would serve the function well. Using a filter 28 within the bleed device 26 or in the line upstream thereof can help prevent plugging of the bleed device 26.

[0012] The downhole tool actuating arrangement 10 is positionable within a borehole structure 30 such as a liner, casing or open hole, for example. In one embodiment the check valve 22 is above a tubing hanger 34 while the bleed device 26 is below the tubing hanger 34 but above a production packer 38. Alternately, the check valve 22 can be positioned below the production packer 34. The bleed device 26 exhausts through exhaust line 40 into an annulus 42 defined between a tool string 46 supporting the arrangement 10 and the structure 30. An optional exhaust check valve 50 may be included in the exhaust line 40 of the bleed device 26. One purpose for the exhaust check valve 50 is to prevent reverse flow through the bleed device 26. If employed the exhaust check valve 50 may be set to open at pressures low enough to avoid interfering with the functioning of the bleed device 26. The packers 38 separate individual production zones 58 of an earth formation 60 from one another with the downhole tools 18 being positioned within each of the production zones 58. Perforations 64 in the structure 30 allow fluid communication between the zones 58 and the annulus 42.

[0013] The foregoing structure allows an operator to actuate the plurality of downhole tools 18 with just the single control line 14. This is made possible in part by use of a plurality of multi-cycle devices described herein a single line switches (SLS) 62. The single line switches 62 require pressure pulses supplied in one embodiment via the control line 14, to be able to actuate one or more of the downhole tools 18 in operable communication with the single line switches 62. Copending application with attorney docket No. ICN4-57960-US-NP/BAO1264US, listed above, discloses a single line switch that is employable herein as the single line switches 62. Unlike the arrangement 10 disclosed herein, in conventional systems that include one of the check valves 22 there is not a designed-in and controllable way for the pressure within the control system 12 to decrease. Inclusion of the bleed device 26 in the arrangement 10 provides this designed-in and controllable device for bleeding fluid from the control system 12 to allow pressure within the control system 12 to decrease in a relatively short time period. In fact, this pressure reduction time can be cut to minutes as opposed to hours and days for conventional systems that do not include the bleed device 26. Optionally, the exhaust line 40 can be fluidically connected to an exhaust line 66 from one of the single line switches 62 as shown in FIG. 2, or the two exhaust lines 40 and 66 can be routed independently of one another.

[0014] The drops in pressure within the control line 14 can also allow the single line switches 62 or the downhole tools 18 to reset. Based on the design of the single line switches 62 and the downhole tools 18 this resetting can be performed automatically in response to pressure reductions in the control system 12 dropping below a threshold value. One example of a downhole tool 18, is the valves disclosed in copending application with attorney docket No. ICN4-57960-US-NP/BAO1264US, listed above (as valves 14 and 16). It should be noted however, that the downhole tool 18 could be any tool that is actuated by increases in pressure.

[0015] Additionally, parts of the downhole actuating arrangement 10 can be incorporated at different points in time. For example, the control system 12 and the bleed device 26 can be retrofitted to a system having one of the check valves 22 that has already been in operation for a period of time. Stated another way, a pre-existing wellbore, that includes one of the check valves 22 can be retrofitted with the control system 12 and the bleed device 26 thereby creating the arrangement 10 disclosed herein. One or more of the downhole tools 18 and one or more of the single line switches 62 can also be retrofitted with the control system 12 and bleed device 26. In such a retrofitting arrangement the control system 12 is fluidically connected to a portion 70 of an existing wellhead or control system. Such a retrofit allows addition of one or more of the downhole tools 18 to be added that are actuatable and resettable through the existing single control line 14, for example.

[0016] In addition to adding this new functionality to an existing well that already includes one of the check valves 22 the downhole tool actuating arrangement 10 could just as well be incorporated into a new well. Regardless of whether the actuating arrangement is incorporated into a new or retrofitted well it overcomes a potential difficulty in actuating or resetting the downhole tools 18 when one of the check valves 26 is employed in the control line 18. This difficulty stemming from the length of time required for pressure in the control line 14 to reduce after having been increased since fluid is not permitted to flow in a reverse direction through the control line 14. The inclusion of the check valve 26, above a wellhead for example, is becoming more common and could even become mandatory at some point to prevent potential leakage from a well through the control line 14 should the control line 14 become severed, for example.

[0017] While the invention has been described with reference to an exemplary embodiment or embodiments, it will be understood by those skilled in the art that various changes may be made and equivalents may be substituted for elements thereof without departing from the scope of the invention. In addition, many modifications may be made to adapt a particular situation or material to the teachings of the invention without departing from the essential scope thereof. Therefore, it is intended that the invention not be limited to the particular embodiment disclosed as the best mode contemplated for carrying out this invention, but that the invention will include all embodiments falling within the scope of the claims. Also, in the drawings and the description, there have been disclosed exemplary embodiments of the invention and, although specific terms may have been employed, they are unless otherwise stated used in a generic and descriptive sense only and not for purposes of limitation, the scope of the invention therefore not being so limited. Moreover, the use of the terms first, second, etc. do not denote any order or importance, but rather the terms first, second, etc. are used to distinguish one element from another. Furthermore, the use of the terms a, an, etc. do not denote a limitation of quantity, but rather denote the presence of at least one of the referenced item.

User Contributions:

Comment about this patent or add new information about this topic:

| People who visited this patent also read: | |

| Patent application number | Title |

|---|---|

| 20200259712 | MODEL-DRIVEN SERVICE ROLLBACK MECHANISM FOR DATA INTEGRITY |

| 20200259711 | COMMUNICATION SYSTEM AND METHOD |

| 20200259710 | System and Method for Onboarding IOT Devices |

| 20200259709 | FABRIC-BASED VIRTUAL AIR GAP PROVISIONING, SYSTEMS AND METHODS |

| 20200259707 | PROVIDING LOGICAL NETWORKING FUNCTIONALITY FOR MANAGED COMPUTER NETWORKS |