Patent application title: Spill Resistant Fluid Container Apparatus

Inventors:

Michael R. Schramm (Perry, UT, US)

Michael R. Schramm (Perry, UT, US)

IPC8 Class: AB65D4736FI

USPC Class:

2203671

Class name: Receptacles closures vent in closure

Publication date: 2016-01-28

Patent application number: 20160023822

Abstract:

The present invention is a spill resistant fluid container apparatus that

eliminates the need for pouring of liquid such as bubble solution into or

out of the spill resistant container apparatus in order to use the spill

resistant container apparatus. The apparatus, which is preferably

provided with bubble solution sealingly contained within the apparatus,

will, when opened, prohibit the pouring of liquid out of the apparatus

regardless of the physical orientation of the apparatus. The apparatus is

preferably of such low cost construction that the apparatus is readily

disposable after the bubble solution contained within the apparatus is

substantially consumed.Claims:

1. A container adapted to spill resistantly contain bubble creation

solution while providing access to said solution, said container having

an inner cavity and at least one opening covered by at least one flexible

seal having a slit formed therein, and a wherein said container defines a

single non-destructively inseparable structural member.

2. The container of claim 1, wherein said flexible seal is substantially watertightly sealed within said container by a frangible seal.

3. The container of claim 1, wherein bubble creation solution is substantially watertightly sealed within said container by a frangible seal.

4. The container of claim 1, wherein said flexible seal is adapted to allow the passage of a fluid access device into said container through said flexible seal slit.

5. The container of claim 4, wherein said fluid access device defines a bubble creation wand, and wherein said bubble creation wand is at least partially removably positioned within said container.

6. The container of claim 1, wherein said flexible seal further defines a substantially self-resealing seal.

7. The container of claim 1, wherein said flexible seal further defines an elastomeric seal.

8. The container of claim 1, wherein said flexible seal further defines a concave shaped seal adapted such that when said slit is object-free and a fluid exerts a hydrostatic load against said flexible seal, said hydrostatic load causes closure loading of said flexible seal to increase.

9. The container of claim 1, wherein said container further defines the non-destructively inseparable assembly of a bottle and a collar, and wherein said collar includes said flexible seal affixed thereto.

10. A container adapted to hermetically contain bubble creation solution and adapted to provide spill resistant access to said bubble creation solution after hermeticity termination, said container having an inner cavity and at least one opening covered by at least one flexible seal, said flexible seal being substantially watertightly sealed within said container by a frangible seal.

11. The container of claim 10, wherein said flexible seal flexible includes a slit formed therein.

12. The container of claim 10, wherein said container further includes bubble creation solution substantially watertightly sealed within said container by said frangible seal.

13. The container of claim 10, wherein said flexible seal flexible includes a slit formed therein, and wherein said flexible seal is adapted to allow the passage of a fluid access device into said container through said flexible seal slit.

14. The container of claim 13, wherein said fluid access device defines a bubble creation wand, and wherein said bubble creation wand is at least partially removably positioned within said container.

15. The container of claim 10, wherein said flexible seal further defines a substantially self-resealing seal.

16. The container of claim 10, wherein said flexible seal further defines an elastomeric seal.

17. The container of claim 11, wherein said flexible seal further defines a concave shaped seal adapted such that when said slit is object-free and a fluid exerts a hydrostatic load against said flexible seal, said hydrostatic load causes closure loading of said flexible seal to increase.

18. The container of claim 10, wherein said container further defines the non-destructively inseparable assembly of a bottle and a collar, and wherein said collar includes said flexible seal affixed thereto.

19. A container adapted to hermetically contain bubble creation solution and adapted to provide spill resistant access to said bubble creation solution after hermeticity termination, said container having an inner cavity and at least one opening covered by at least one flexible seal having a slit formed therein, said flexible seal and a quantity of bubble creation solution being substantially watertightly sealed within said container by a frangible seal.

20. The container of claim 19, wherein said flexible seal further defines a substantially self-resealing concave shaped elastomeric seal adapted to allow passage of a bubble creation wand into said container through said flexible seal slit and adapted such that when said slit is object-free and a fluid exerts a hydrostatic load against said flexible seal, said hydrostatic load causes closure loading of said flexible seal to increase, and wherein a bubble creation wand is at least partially removably positioned within said container.

Description:

CROSS REFERENCE TO RELATED APPLICATIONS

[0001] This nonprovisional utility patent application claims the benefit under 35 U.S.C. §119(e) of U.S. provisional application No. 61/553,172, filed Oct. 29, 2011, which is incorporated herein, in its entirety, by this reference.

FIELD OF THE INVENTION

[0002] The present invention relates to spill resistant containers and more especially to unitary integral single-structure non-destructively inseparable spill resistant bubble solution containers.

BACKGROUND OF THE INVENTION

[0003] Ever since the commercialization of the spill proof bubble solution container invention disclosed in the Schramm U.S. Pat. No. 5,246,046 patent, spill proof bubble solution containers have been widely popular, have become a standard in the industry and have provided autonomy and enjoyment for young children in creating bubbles without the mess that otherwise occurs when using conventional bubble creation wands. Examples of such containers are disclosed in the following patents and applications, all of which are expressly incorporated herein by reference: U.S. Pat. Nos. 7,942,109, 7,524,230, 7,244,161, 6,857,928, 6,638,131, 6,629,870, 6,595,822, 6,520,822, 6,386,138, 6,186,853, 6,135,842, 6,015,327, 5,908,057, 5,832,969, 5,495,876, 5,304,085, 5,246,046, 5,105,975, 5,088,950, 4,957,464, 4,840,597, 4,180,938, 3,579,898, 2,858,639, RE42,610, RE39,443, RE36,131, 20110081821, 20080289975, 20050130552, 20040084453, 20030155364, 20020187716, 20020129763, 20010035413, D600,290, Ser. Nos. 12/539,803, 13,234,265, and EU0094532.

[0004] Over the years, many different embodiments of the spill proof bubble solution container have been produced by many different manufacturers. However, all such prior art spill resistant containers have suffered from a common problem, namely all such containers, while typically reusable--i.e. they can be repeatedly re-filled with bubble creation solution and re-used in creating bubbles--typically require the user to disassemble the container, remove or open a frangible seal, pour bubble solution into the container usually to a noted predetermined level (or in one case pour bubble solution out of the container), and reassemble the container prior to use. It is this disassembly, seal removal, pouring, filling, and reassembly that is the source of much spilling and reduces the autonomy of the user (typically a child who is typically dependent on an adult to disassemble, remove or open a frangible seal, pour, fill, and reassemble the container). In at least one instance of the prior art, the container does not require disassembly, but in this instance, the funnel opening is of such a small size, that pouring bubble solution into the funnel opening without spilling is extremely difficult. A product table (corresponding to the Non-Patent Literature included in the information disclosure statement filed with this application) has been prepared to provide information on known production spill resistant bubble solution containers. The table includes the respective method of use of the container.

[0005] Several known prior art containers are particularly noteworthy examples of the problems with the state-of-the-art product. In a first instance, the "Spill Proof Tweety Bubble Necklace" (NPL C15), in a design aspect atypical from of spill resistant containers, is of non-disassemblable multiple-piece construction, with the only opening of the container being the funnel opening. Thus it is through the funnel opening that bubble solution must be poured in order to use the container. The funnel opening is extremely small rendering the product extremely difficult to fill without spilling. In a second instance, the "No Spill Miracle Bubbles" (NPL C18), is provided with a "full" sealed container of bubble solution (a conventional bottle of bubble solution) and a "No Spill Cap". In order to use the product, the user must first remove a frangible seal, pour out at least half of the bubble solution from the bottle into some other (not provided) container. Not only are the seal removal process and the pouring process highly prone to spilling, but while the user is using the product the extra bubble solution is stored in some "other" container which itself may be highly susceptible to spillage, including by the user as the user is using the product. In a third instance, to use either the "Spill Resist Cap" (NPL-C39 and based on U.S. Pat. No. 4,180,938 and U.S. Pat. No. 5,088,950) or the "Spill Stopper Cap" (NPL C23 and based on D600,290, and 20080289975), the user must remove the Spill Resist Cap or the "original cap" respectively, rupture or remove the frangible seal from a conventional bottle of bubble solution (a process which in itself is highly spill prone) and then assemble the Spill Resist Cap or the Spill Stopper Cap respectively to the conventional bottle of bubble solution. Thus again, either the likelihood of spilling by a child is increased or the autonomy of a child is reduced. In a fourth instance, to use either the "Spill Resist Cap" (NPL-C42) or the "Popeye Bubble Factory" (NPL C43), the user must either remove the lid having the slot and pour bubble solution into a relatively small rectangular opening (a process which in itself is highly spill prone) or worse the user must flex the spill resistant membrane and then pour bubble solution through the opening (a process which virtually guaranteed to result in spilled bubble solution). Thus yet again, either the likelihood of spilling by a child is increased or the autonomy of a child is reduced.

TABLE-US-00001 PRODUCT TABLE Product Company NPL Method of Preparation No-Spill Bubble Tumbler Little Kids C1 Unscrew lid from cup. Pour solution into cup. Reassemble container. No-Spill Bubble Tumbler Mini Little Kids C2 Unscrew lid from cup. Pour solution into cup. Reassemble container. No-Spill Bubble Tumbler Little Kids C3 Unscrew lid from cup. Pour solution into cup. Micro Mini Reassemble container. No-Spill Big Bubble Bucket Little Kids C4 Unscrew lid from cup. Pour solution into cup. Reassemble container. No-Spill Mini Bubble Bucket Little Kids C5 Unscrew lid from cup. Pour solution into cup. Reassemble container. No-Spill Bubble Mug Little Kids C6 Unscrew lid from cup. Pour solution into cup. Reassemble container. Cowboy Bubble Shooter and Little Kids C7 Pour solution into (non-disassemblable No-Spill Bubble Holster multiple-piece construction) holster. No-Spill Motorized Dip 'N Little Kids C8 Pour solution into (disassemblable) dip tray. Blow Bubbles No-Spill Bubble Dooods Little Kids C9 Unscrew lid from cup. Pour solution into cup. Reassemble container. Spill Proof Mr. Bubbles Strombecker C10 Unscrew funnel from container. Pour solution into container. Reassemble container. Spill Proof Bubble Rocket Strombecker C11 Unscrew funnel from container. Pour solution into container. Reassemble container. Spill Proof Elmo's Bubble Fun Strombecker C12 Unscrew lid from cup. Pour solution into cup. Reassemble container. Spill Proof Marvin The Strombecker C13 Unscrew funnel from container. Pour solution Martian Bubble Spaceship into container. Reassemble container. Spill Proof Hunny Pot Strombecker C14 Unscrew funnel from container. Pour solution into container. Reassemble container. Spill Proof Tweety Bubble Strombecker C15 Pour solution into (non-disassemblable Necklace multiple-piece construction) container. Spill Proof Container with Strombecker C16 Unscrew lid from cup. Pour solution into cup. Auxiliary Handle Reassemble container. Mini Spill Proof Strombecker C17 Unscrew lid from cup. Pour solution into cup. Reassemble container. No Spill Miracle Bubbles Imperial Toy C18 Unscrew funnel from bottle. Remove frangible seal. Pour solution into (or out of) bottle. Reassemble container. No Spill Bubble Submarine Imperial Toy C19 Unscrew funnel from container. Pour solution into container. Reassemble container. No Spill Bubble Cell Phone Imperial Toy C20 Remove plug from container. Pour solution into (small) opening in container. No Tip No Spill Tumbler Imperial Toy C21 Unscrew funnel from container. Pour solution into container. Reassemble container. No Spill Bubbles 'N Sand Imperial Toy C22 Unscrew lid from cup. Pour solution into cup. Bucket Reassemble container. Spill Stopper Imperial Toy C23 Unscrew lid from bottle. Remove frangible seal. Screw spill stopper lid to bottle. No Spill Bubble Buddy Little Tykes C24 Unscrew lid from cup. Pour solution into cup. Reassemble container. No Spill Bubble Bucket Little Tykes C25 Unscrew lid from cup. Pour solution into cup. Reassemble container. Super Non-Spill Double Placo C26 Unscrew lid from cup. Pour solution into cup. Tumbler Reassemble container. Pivot Top Spill Resistant Placo C27 Unscrew lid from cup. Pour solution into cup. Bubbles Reassemble container. Spill Resistant Giant Bucket Placo C28 Unscrew lid from cup. Pour solution into cup. Reassemble container. Spill Resistant (Mini) Bucket Placo C29 Unscrew lid from cup. Pour solution into cup. Reassemble container. Never Spill Bubbles Tanget Toy C30 Unscrew lid from (multiple-piece) container. (ToySmith) Pour solution into container. Reassemble. Non Spill Bubble Tumbler Battat C31 Unscrew funnel from container. Pour solution into container. Reassemble container. No Spill Tumbler Flair/Funrise C32 Unscrew lid from cup. Pour solution into cup. Reassemble container. (Non Spill) Bubble Bouncer Funrise C33 Unscrew lid from cup. Pour solution into cup. Reassemble container. Bubble Wubble Tumbler Funrise C34 Unscrew lid from cup. Pour solution into cup. Reassemble container. Weeble Wobble Bubble Bottle Hasbro C35 Unscrew lid from cup. Pour solution into cup. Reassemble container. No-Spill Canteen (Bubble Toys R Us C36 Unscrew funnel from container. Pour solution Explorer) into container. Reassemble container. Barbie Baubles 'N bubbles Toy Quest C37 Unsnap top from bottom. Pour solution into Bubble Purse bottom. Reassemble container. No Spill Bubble Bucket Pustefix C38 Unscrew lid from cup. Pour solution into cup. Reassemble container. Spill Resist Cap Hasbro C39 Unscrew spill resist cap from bottle. Remove frangible seal. Screw spill resist cap to bottle. No Spill Mr. Potato Head Hasbro C40 Remove lid from cup. Pour solution into cup. Reassemble container. Bubble Brush TOI C41 Optionally remove lid from cup or pour solution into assembled container. Spill Resist Cap TOI C42 Optionally remove lid from cup or pour solution into assembled container. Popeye Bubble Factory Tak-A-Toy C43 Optionally remove lid from cup or pour solution into assembled container. Bubble Blowing Glider Remco C44 Pour solution into container.

SUMMARY OF THE INVENTION

[0006] The present invention is a spill resistant fluid container apparatus that eliminates the need for spill prone pouring of liquid such as bubble solution. The apparatus preferably defines a single nondestructively inseparable spill resistant container assembly having a neck, a flexible seal having a preferably self-sealing slit, a frangible seal, a lid, bubble creation solution, and a bubble creation wand. The bubble creation solution is sealingly contained within the container by the frangible seal and the lid is preferably threadingly and removably attached to the neck of the container. No pouring or filling of bubble creation solution is required for a user in using the apparatus to creating bubbles. In order to use the apparatus in creating bubbles, one need only threadingly remove the lid, tear open the frangible seal, insert a bubble creation wand through the slit, remove the bubble creation wand, and blow a bubble. From the point of purchase of the apparatus until the bubble creation solution of the apparatus is consumed, there is never an occasion wherein the container needs to be disassembled or reassembled, and thus there is never an opportunity for gross spillage of the bubble creation solution. By avoiding the disassembly, assembly, and pouring required of the prior art, in contrast to the prior art, there is never a point wherein the instant spill resistant container apparatus invention is rendered non-spill-resistant.

DESCRIPTION OF DRAWINGS

[0007] In order that the advantages of the invention will be readily understood, a more particular description of the invention briefly described above will be rendered by reference to specific embodiments that are illustrated in the appended drawings. Understanding that these drawings depict only typical embodiments of the invention and are not therefore to be considered to be limiting of its scope, the invention will be described and explained with additional specificity and detail through the use of the accompanying drawings, in which:

[0008] FIG. 1 is an isometric view of a first embodiment of the spill resistant fluid container apparatus;

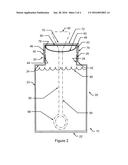

[0009] FIG. 2 is an orthographic side section view a first embodiment of the spill resistant fluid container apparatus taken substantially at the location of section arrows 2 shown in FIG. 1 and is shown in a pre-opened configuration with the bubble creation solution sealed within the container and the lid threaded onto the container, and with the bubble creation wand shown in phantom lines and positioned where it would be in use in a post-opened configuration;

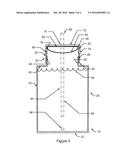

[0010] FIG. 3 is an orthographic side section view a first embodiment of the spill resistant fluid container apparatus taken substantially at the location of section arrows 3 shown in FIG. 1 and is shown in a pre-opened configuration with the bubble creation solution sealed within the container and the lid threaded onto the container, and with the bubble creation wand shown in phantom lines and positioned where it would be in use in a post-opened configuration, and;

[0011] FIG. 4 is a top or plan view of just the collar device of the spill resistant fluid container apparatus with the flexible seal shown in an unflexed state and with the flexible seal slit shown in a self-sealingly closed state.

DETAILED DESCRIPTION OF THE INVENTION

[0012] Reference throughout this specification to "one embodiment," "an embodiment," or similar language means that a particular feature, structure, or characteristic described in connection with the embodiment is included in at least one embodiment of the present invention. Thus, appearances of the phrases "in one embodiment," "in an embodiment," and similar language throughout this specification may, but do not necessarily, all refer to the same embodiment.

[0013] Furthermore, the described features, structures, or characteristics of the invention may be combined in any suitable manner in one or more embodiments. In the following description, numerous specific details are included to provide a thorough understanding of embodiments of the invention. One skilled in the relevant art will recognize, however, that the invention can be practiced without one or more of the specific details, or with other methods, components, materials, and so forth. In other instances, well-known structures, materials, or operations are not shown or described in detail to avoid obscuring aspects of the invention.

[0014] In order to facilitate the understanding of the present invention in reviewing the drawings accompanying the specification, a feature table is provided below. It is noted that like features are like numbered throughout all of the figures.

TABLE-US-00002 FEATURE TABLE # Feature 10 Spill resistant fluid container apparatus 20 Container 22 Container bottom 23 Container side 24 Container top 26 Container neck 28 Container threads 30 Collar Device 40 Collar 42 Collar Lower End 43 Collar Upper End 44 Collar Internal Threads 46 Collar External Threads 48 Collar seal surface 50 Flexible Seal 52 Flexible Seal Slit 60 Frangible Seal 70 Lid 72 Lid top 74 Lid flange 76 Lid threads 80 Bubble creation wand 82 Wand handle 84 Wand stem 86 Wand ring 90 Bubble creation solution

[0015] Referring now to the drawings, and in particular to FIGS. 1 through 4, the first embodiment of the invention is a spill resistant fluid container apparatus 10 for use in creating bubbles without the otherwise attendant spillage of bubble solution resulting from opening a seal of a conventional container of bubble solution or from pouring bubble solution into or out of the apparatus comprising a container 20, a frangible seal 60, a lid 70, a bubble creation wand 80, and bubble creation solution 90. Container 20 defines a generally cylindrical shaped preferably one-piece plastic container defining an inner cavity and having a bottom 22, a side 23, a top 24, a neck 26, and threads 28. Container 20 is preferably constructed such as by blow-molding so as to be of significantly low cost and preferably disposable after the bubble solution that is provided seal within container 20 is consumed. Collar device 30 comprises collar 40 and flexible seal 50. Collar 40 defines a preferably generally hollow cylindrically shaped plastic injection molded collar having a lower end 42, an upper end 43, internal threads 44, external threads 46, and a seal surface 48. Flexible seal 50 defines a preferably diaphragm-like convex elastic seal (such as the seal of US 200802899775to Sharber) having a preferably self-sealing flexible seal slit 52. Collar device 30 is preferably created by an insert injection molding process using flexible seal 50 as the insert and injection molding collar 40 around flexible seal 50. Frangible seal 60 preferably defines an adhesively bondable disk shaped frangible metal foil seal but alternately may be of other shapes and may be of other seal material such as a non-metal seal. Frangible seal 60 preferably includes a tab portion that may be grasped in order to break open or peel open frangible seal 60. Lid 70 preferably defines conventional generally cylindrically shaped injection molded plastic lid having a top 72, a flange 74, and threads 76. Bubble creation wand 80 defines a generally elongated wand preferably plastic injection molded wand having a handle 82, a stem 84, and at least one bubble creation ring 86. Bubble creation ring 86 preferably includes a plurality of fins extending from bubble creation ring 86 to increase the surface area of bubble creation ring 86 resulting in an increased bubble solution retention capacity. Bubble creation solution 90 defines a conventional liquid bubble creation solution such as a glycerin based liquid bubble creation solution.

[0016] Spill resistant fluid container apparatus 10 is assembled by sealingly and permanently affixing collar device 30 to container 20. Such affixing is preferably accomplished by adding an adhesive sealant to threads 28 and or threads 44, and then threading collar device 30 onto container 20. Alternatively, collar device 30 may be welded to container 20 such as by ultrasonic welding. Further alternatively, the resultant structure of the combined collar device 30 and container 20 may be molded as a single structure such as by blow molding followed by secondary forming and slitting processes. With collar device 30 affixed to container 20, bubble creation solution 90 is added to container 20 such as by metering a predetermined quantity of bubble creation solution 90 into spill resistant container 20 via a fill nozzle connected to a filling machine and inserted through flexible seal slit 52. Frangible seal 60 is then sealingly attached to collar device 30 by adhesively bonding frangible seal 60 to seal surface 48 such that the combination of container 20, collar device 30, and bonded frangible seal 60 preferably form a substantially hermetically sealed container assembly. Lid 70 is threadingly connected to collar device 30 by engaging threads 76 and threads 46 and by rotating or screwing lid 70 onto collar upper end 43 of collar device 30.

[0017] In practice, spill resistant fluid container apparatus 10 is purchased as defined above with bubble creation solution 90 sealingly contained within container 20. A user, such as a young child, detaches lid 70 from container 20 by unscrewing lid 70 from collar device 30. The user then breaks or otherwise removes frangible seal 60. It is noted that although the frangible seal 60 opening or removal process is highly spill prone when performed on a conventional bottle of bubble solution, because flexible seal 50 is positioned between frangible seal 60 and bubble creation solution 90, bubble creation solution 90 remains spill resistantly contained in container 20 throughout the frangible seal 60 opening or removal process. The user then inserts bubble creation wand 80 into bubble creation solution 90 by passing bubble creation wand 80 through flexible seal slit 52 of flexible seal 50, causing flexible seal slit 52 to flex just enough to allow the passage of bubble creation wand 80 but not so much as to create a large gap through which bubble creation solution 90 could otherwise spill. Bubble creation wand 80 is then withdrawn from container 20, causing flexible seal slit 52 to substantially re-self-seal and causing bubble creation wand 80 to be charged with bubble creation solution 90. It is noted that due to the flexible nature of flexible seal 50 and due to the concavity of flexible seal 50, when bubble creation wand 80 is withdrawn from container 20 and bubble creation solution 90 is pressing against flexible seal 50 and would otherwise run out of container 20, hydrostatic pressure of bubble creation solution 90 against flexible seal 50 further causes flexible seal slit 52 to sealingly close. The user then creates bubbles by blowing into bubble creation ring 86. Once bubble creation solution 90 is consumed from bubble creation wand 80, bubble creation wand 80 is again inserted into container 20. The bubble creation process is then repeated until the user tires of creating bubbles or until bubble creation solution 90 contained within container 20 is consumed. If bubble creation solution 90 contained within container 20 is not consumed but the user tires of creating bubbles, lid 70 is replaced onto collar device 30 so as to prevent debris ingress and spill resistant fluid container apparatus 10 is stored for subsequent use. If bubble creation solution 90 previously contained within container 20 is consumed, the user merely discards spill resistant fluid container apparatus 10. It is noted that container 20 will prevent spillage of bubble creation solution 90 regardless of the orientation in which container 20 may be positioned. It is further noted that short of destructively altering spill resistant fluid container apparatus 10, the user is prevent from ever pouring bubble creation solution 90 out of container 20, and that the user need never pour bubble creation solution into or out of container 20 in order to use spill resistant fluid container apparatus 10, thus furthering the spill resistant utility of spill resistant fluid container apparatus 10.

[0018] The present invention may be embodied in other specific forms without departing from its spirit or essential characteristics. The described embodiments are to be considered in all respects only as illustrative and not restrictive. The scope of the invention is, therefore, indicated by the appended claims rather than by the foregoing description. All changes which come within the meaning and range of equivalency of the claims are to be embraced within their scope.

User Contributions:

Comment about this patent or add new information about this topic: