Patent application title: Sealing Device for Automatic Bagging Machine

Inventors:

Chang-Shuen Hsu (Chiayi County, TW)

IPC8 Class: AB65B5110FI

USPC Class:

53285

Class name: Package making closing packages and filled receptacles

Publication date: 2016-01-28

Patent application number: 20160023791

Abstract:

A sealing device for an automatic bagging machine contains: a film

sealing assembly including a first seal, a second seal mount opposite to

the first seal mount; a slide assembly including an elongated plate, a

rail arranged on the elongated plate, and a sliding piece fixed on the

rail; a cutting module including a cylinder seat, a mounting sheet, four

screwing elements, a driving cylinder, and a roller. The cylinder seat is

mounted on one side surface of the sliding piece, and the driving

cylinder and the roller are inserted through the second seal mount.

Between the cylinder seat and the mounting sheet are defined a central

shaft and two gaps on two sides of the central shaft. In addition, at

least two springs are arranged between the cylinder seat and the mounting

sheet and are fitted on the four screwing elements.Claims:

1. A sealing device for an automatic bagging machine comprising: a film

sealing assembly including a first seal mount disposed on a left side

thereof and being a hollowly elongated frame, a second seal mount mounted

on a right side thereof opposite to the first seal mount and being a

hollowly elongated frame; a slide assembly including an elongated plate,

a rail arranged on one side of the elongated plate, and a sliding piece

fixed on the rail; a cutting module including a cylinder seat, a mounting

sheet connected with the cylinder seat, four screwing elements screwed

with the cylinder seat through four corners of a first side of the

mounting sheet, a driving cylinder secured on a second side of the

mounting sheet, and a roller disposed on the driving cylinder; the

cylinder seat being mounted on one side surface of the sliding piece, and

the driving cylinder and the roller being inserted through the second

seal mount; characterized in that: between the cylinder seat and the

mounting sheet are defined a central shaft and two gaps on two sides of

the central shaft.

2. The sealing device for the automatic bagging machine as claimed in claim 1, wherein at least two springs are arranged between the cylinder seat and the mounting sheet and are fitted on the screwing elements.

Description:

BACKGROUND OF THE INVENTION

[0001] 1. Field of the Invention

[0002] The present invention relates to a sealing device for an automatic bagging machine in which a cutting module is adjusted easily to control tightness between a film and a yarn cylinder.

[0003] 2. Description of the Prior Art

[0004] A conventionally sealing device of a bagging machine is employed to cut a yarn cylinder and to seal a film around the yarn cylinder, thus packing the yarn cylinder.

[0005] As illustrated in FIG. 10, a cutting module 10 of the conventionally sealing device contains a cylinder seat 20, a mounting sheet 30, a cylinder 50, and a roller 60. The cylinder seat 20 is connected with the mounting sheet 30, and four screwing elements 40 are screwed with the cylinder seat 20 through the mounting sheet 30. The mounting sheet 30 is coupled with the cylinder 50, and the cylinder 50 is joined with the roller 60.

[0006] The conventional sealing device of the bagging machine can cut the yarn cylinder and can seal the film around the yarn cylinder, but it cannot control tightness between the film and the yarn cylinder.

[0007] The present invention has arisen to mitigate and/or obviate the afore-described disadvantages.

SUMMARY OF THE INVENTION

[0008] The primary objective of the present invention is to provide a sealing device for an automatic bagging machine in which a central shaft of a cutting module is applied to adjust an angle of the cutting module, thereby controlling a film for sealing a yarn cylinder.

[0009] To obtain the above objectives, a sealing device for an automatic bagging machine provided by the present invention contains:

[0010] a film sealing assembly including a first seal mount disposed on a left side thereof and being a hollowly elongated frame, a second seal mount mounted on a right side thereof opposite to the first seal mount and being a hollowly elongated frame;

[0011] a slide assembly including an elongated plate, a rail arranged on one side of the elongated plate, and a sliding piece fixed on the rail;

[0012] a cutting module including a cylinder seat, a mounting sheet connected with the cylinder seat, four screwing elements screwed with the cylinder seat through four corners of a first side of the mounting sheet, a driving cylinder secured on a second side of the mounting sheet, and a roller disposed on the driving cylinder; the cylinder seat being mounted on one side surface of the sliding piece, and the driving cylinder and the roller being inserted through the second seal mount.

[0013] Between the cylinder seat and the mounting sheet are defined a central shaft and two gaps on two sides of the central shaft.

BRIEF DESCRIPTION OF THE DRAWINGS

[0014] FIG. 1 is a perspective view showing the assembly of a sealing device for an automatic bagging machine according to a first embodiment of the present invention.

[0015] FIG. 2 is a perspective view showing the assembly of a part of the sealing device for the automatic bagging machine according to the first embodiment of the present invention.

[0016] FIG. 3 is a cross sectional view showing the assembly of a part of the sealing device for the automatic bagging machine according to the first embodiment of the present invention.

[0017] FIG. 4 is a cross sectional view showing the assembly of a part of a sealing device for an automatic bagging machine according to a second embodiment of the present invention.

[0018] FIG. 5 is a cross sectional view showing the operation of a part of the sealing device for the automatic bagging machine according to the first embodiment of the present invention.

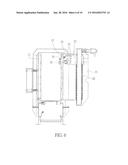

[0019] FIG. 6 is a front plan view showing the operation of a part of the sealing device for the automatic bagging machine according to the first embodiment of the present invention.

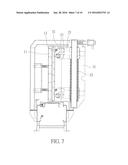

[0020] FIG. 7 is another front plan view showing the operation of a part of the sealing device for the automatic bagging machine according to the first embodiment of the present invention.

[0021] FIG. 8 is a side plan view showing the operation of a part of the sealing device for the automatic bagging machine according to the first embodiment of the present invention.

[0022] FIG. 9 is another side plan view showing the operation of a part of the sealing device for the automatic bagging machine according to the first embodiment of the present invention.

[0023] FIG. 10 is a perspective view of a part of a cutting module of a conventional sealing device for an automatic bagging machine.

DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS

[0024] The present invention will be clearer from the following description when viewed together with the accompanying drawings, which show, for purpose of illustrations only, a preferred embodiment in accordance with the present invention.

[0025] With reference to FIGS. 1-3, a sealing device for an automatic bagging machine according to a first embodiment of the present invention comprises:

[0026] a film sealing assembly 1 including a first seal mount 11 disposed on a left side thereof and being a hollowly elongated frame, a second seal mount 12 mounted on a right side thereof opposite to the first seal mount 11 and being a hollowly elongated frame;

[0027] a slide assembly 2 including an elongated plate 21, a rail 22 arranged on one side of the elongated plate 21, and a sliding piece 23 fixed on the rail 22;

[0028] a cutting module 3 including a cylinder seat 31, a mounting sheet 32 connected with the cylinder seat 31, four screwing elements 33 screwed with the cylinder seat 31 through four corners of a first side of the mounting sheet 32, a driving cylinder 34 secured on a second side of the mounting sheet 32, and a roller 35 disposed on the driving cylinder 34; the cylinder seat 31 being mounted on one side surface of the sliding piece 23, and the driving cylinder 34 and the roller 35 being inserted through the second seal mount 12; characterized in that:

[0029] between the cylinder seat 31 and the mounting sheet 32, are defined a central shaft 36 and two gaps 361 on two sides of the central shaft 36, such that at least two springs 37 are arranged between the cylinder seat 31 and the mounting sheet 32 and are fitted on the four screwing elements 33 (as shown in FIG. 4).

[0030] Referring further to FIGS. 5-9, after a yarn cylinder 4 passes through the film sealing assembly 1, the first seal mount 11 and the second seal mount 12 executes sealing and cutting operation, the sliding piece 23 of the slide assembly 2 slides downwardly along the rail 22 to drive the cutting module 3 to move downwardly, and the roller 35 cuts a film for sealing the yarn cylinder 4. Thereafter, a user reviews whether the film contacts with the yarn cylinder 4 and adjusts the four screwing elements 33 opposite to the central shaft 36 so that the mounting sheet 32 tilts into the two gaps 361. Alternatively, the user adjusts the at least two springs 37 to form an inward angle or an inward angle for pulling or releasing the film, thus controlling tightness between the film and the yarn cylinder.

[0031] While various embodiments in accordance with the present invention have been shown and described, it is clear to those skilled in the art that further embodiments may be made without departing from the scope of the present invention.

User Contributions:

Comment about this patent or add new information about this topic: