Patent application title: METHODS AND APPARATUSES FOR LIQUEFYING HYDROCARBON STREAMS

Inventors:

Richard Russeff (Bartlesville, OK, US)

IPC8 Class: AF25J100FI

USPC Class:

62611

Class name: Cryogenic treatment of gas or gas mixture liquefaction natural gas

Publication date: 2016-01-07

Patent application number: 20160003526

Abstract:

Methods and apparatuses for liquefying hydrocarbon streams are provided.

In one embodiment, a method for liquefying a hydrocarbon stream includes

expanding the hydrocarbon stream with a turbo expander to form an

expanded hydrocarbon stream. The method includes compressing a first

refrigerant with the turbo expander. Further, the method includes cooling

the expanded hydrocarbon stream with the first refrigerant to form a

liquid hydrocarbon stream.Claims:

1. A method for liquefying a hydrocarbon stream, the method comprising

the steps of: expanding the hydrocarbon stream with a turbo expander to

form an expanded hydrocarbon stream; compressing a first refrigerant with

the turbo expander; and cooling the expanded hydrocarbon stream with the

first refrigerant to form a liquid hydrocarbon stream.

2. The method of claim 1 further comprising separating the expanded hydrocarbon stream into a liquid stream and a vapor stream, wherein cooling the expanded hydrocarbon stream with the first refrigerant comprises cooling the liquid stream and the vapor stream with the first refrigerant.

3. The method of claim 1 further comprising cooling the first refrigerant in a cooling cascade arrangement before cooling the expanded hydrocarbon stream with the first refrigerant.

4. The method of claim 1 further comprising cooling the first refrigerant with a second refrigerant before cooling the expanded hydrocarbon stream with the first refrigerant.

5. The method of claim 1 wherein compressing the first refrigerant with the turbo expander comprises compressing a mixed refrigerant with the turbo compressor.

6. The method of claim 1 further comprising cooling the first refrigerant with a second refrigerant before cooling the expanded hydrocarbon with the first refrigerant.

7. The method of claim 1 further comprising: cooling the first refrigerant with a second refrigerant before cooling the expanded hydrocarbon stream with the first refrigerant, wherein cooling the first refrigerant with the second refrigerant comprises exchanging heat from the first refrigerant to the second refrigerant at a stage in a cooling cascade arrangement.

8. The method of claim 7 wherein cooling the expanded hydrocarbon stream with the first refrigerant comprises exchanging heat from the expanded hydrocarbon stream to the first refrigerant at a later stage in the cooling cascade arrangement.

9. The method of claim 1 wherein cooling the expanded hydrocarbon stream with the first refrigerant comprises exchanging heat from the expanded hydrocarbon stream to the first refrigerant at a stage in a cooling cascade arrangement.

10. The method of claim 9 wherein the cooling cascade arrangement includes a last stage and an upstream stage, and wherein the method further comprises expanding the first refrigerant upstream of the last stage and downstream of the upstream stage.

11. The method of claim 9 further comprising passing the first refrigerant through cooling stages in an upstream cooling cascade before passing the first refrigerant through the cooling cascade.

12. The method of claim 1 further comprising: removing contaminants from the hydrocarbon stream before expanding the hydrocarbon stream to form a contaminant stream; and exchanging heat from the hydrocarbon feed stream to the contaminant stream.

13. A method for liquefying a hydrocarbon stream, the method comprising the steps of: transferring heat from a mixed refrigerant to a second refrigerant at an upstream stage in a cooling cascade; expanding a hydrocarbon stream with a turbo expander to form an expanded hydrocarbon stream; and transferring heat from the expanded hydrocarbon stream to the mixed refrigerant at a downstream stage in the cooling cascade.

14. The method of claim 13 further comprising transferring heat from an entering stream of the mixed refrigerant to an exiting stream of the mixed refrigerant at an additional stage in the cooling cascade.

15. The method of claim 13 further comprising: compressing the mixed refrigerant with the turbo expander to form a compressed mixed refrigerant; and cooling the compressed mixed refrigerant before feeding the mixed refrigerant to the cooling cascade.

16. The method of claim 13 further comprising: compressing the mixed refrigerant with the turbo expander to form a compressed mixed refrigerant; and cooling the compressed mixed refrigerant in a first cooling cascade before feeding the mixed refrigerant to the cooling cascade.

17. The method of claim 13 wherein the cooling cascade is located in a cold box, and wherein the method further comprises: withdrawing the mixed refrigerant from the cold box after transferring heat from the mixed refrigerant to the second refrigerant; expanding the mixed refrigerant; and after expanding the mixed refrigerant, feeding the mixed refrigerant to the downstream stage in the cooling cascade in the cold box.

18. The method of claim 13 further comprising: circulating the first refrigerant through a first loop passing through the cooling cascade; circulating the second refrigerant through a second loop passing through the cooling cascade; feeding the expanded hydrocarbon stream to the cooling cascade; and withdrawing a liquid hydrocarbon stream from the cooling cascade.

19. The method of claim 18 wherein circulating the mixed refrigerant through the first loop comprises circulating the mixed refrigerant through a first cooling cascade and through a compressor zone of the turbo expander.

20. An apparatus for liquefying a hydrocarbon stream, the apparatus comprising: a turbo expander having an expansion zone and a compression zone; a first refrigerant loop including a cooling cascade, wherein the first refrigerant loop passes through the compression zone of the turbo expander; a second refrigerant loop, wherein the second refrigerant loop passes through a first stage in the cooling cascade; and a hydrocarbon stream path, wherein the hydrocarbon stream path passes through the expansion zone of the turbo expander and through a second stage in the cooling cascade.

Description:

TECHNICAL FIELD

[0001] The technical field generally relates to methods and apparatuses for liquefying hydrocarbon streams, and more particularly relates to methods and apparatuses for liquefying natural gas.

BACKGROUND

[0002] Liquefaction of natural gas is routinely practiced as a means of converting natural gas into a more convenient form for transportation and storage. Liquefaction typically reduces the volume of the natural gas by about 600-fold and results in a liquefied natural gas (LNG) product that can be stored and transported at near atmospheric pressure. Removing the need for storage and transport at high pressure reduces costs significantly.

[0003] To store and transport natural gas in the liquid state, the natural gas is preferably cooled to -150° C. to -160° C. (-240° F. to -260° F.) where the liquefied natural gas (LNG) possesses a near-atmospheric vapor pressure. Systems exist for liquefying natural gas by sequentially passing the gas at an elevated pressure through a plurality of cooling stages whereupon the gas is cooled to successively lower temperatures until the liquefaction temperature is reached. Cooling is generally accomplished by indirect heat exchange with one or more refrigerants such as propane, propylene, ethane, ethylene, methane, nitrogen, carbon dioxide, or combinations of the preceding refrigerants (e.g., mixed refrigerant systems).

[0004] Typically, natural gas in the gas phase and comprising predominantly methane, enters an LNG plant at elevated pressures and is pre-treated to produce a purified feed stock suitable for liquefying at cryogenic temperatures. The purified gas is processed through a plurality of cooling stages using heat exchangers to progressively reduce its temperature until liquefaction is achieved. The liquid natural gas is typically further cooled (to reduce flashed vapor through one or more expansion stages) to final atmospheric pressure suitable for storage and transportation.

[0005] The operating costs for liquefying natural gas are high, typically due to the costs of the cooling configuration. Thus any reduction in the energy requirements of the system has cost benefit. Reducing the cost of the cooling configuration may provide significant cost benefit.

[0006] Accordingly, it is desirable to provide improved methods and apparatuses for liquefying hydrocarbon streams. In addition, it is desirable to provide methods and apparatuses that may be incorporated into existing hydrocarbon processing systems to economically produce LNG from recovered gas streams. Furthermore, other desirable features and characteristics will become apparent from the subsequent detailed description and the appended claims, taken in conjunction with the accompanying drawings and the foregoing technical field and background.

BRIEF SUMMARY

[0007] Methods and apparatuses for liquefying hydrocarbon streams are provided. In an exemplary embodiment, a method for liquefying a hydrocarbon stream includes expanding the hydrocarbon stream with a turbo expander to form an expanded hydrocarbon stream. The method includes compressing a first refrigerant with the turbo expander. Further, the method includes cooling the expanded hydrocarbon stream with the first refrigerant to form a liquid hydrocarbon stream.

[0008] In another embodiment, a method for liquefying a hydrocarbon stream includes transferring heat from a first refrigerant to a mixed refrigerant at an upstream stage in a cooling cascade. Further, the method includes expanding a hydrocarbon stream with a turbo expander to form an expanded hydrocarbon stream. The method transfers heat from the expanded hydrocarbon stream to the first refrigerant at a downstream stage in the cooling cascade.

[0009] In accordance with another exemplary embodiment, an apparatus for processing a hydrocarbon stream is provided. The apparatus includes a turbo expander having an expansion zone and a compression zone. The apparatus also includes a first refrigerant loop including a cooling cascade. The first refrigerant loop passes through the compression zone of the turbo expander. Further, the apparatus includes a second refrigerant loop. The second refrigerant loop passes through a first stage in the cooling cascade. A hydrocarbon stream path is provided and passes through the expansion zone of the turbo expander and through a second stage in the cooling cascade.

BRIEF DESCRIPTION OF THE DRAWINGS

[0010] Embodiments of methods and apparatuses for liquefying hydrocarbon streams will hereinafter be described in conjunction with the following drawing figure wherein:

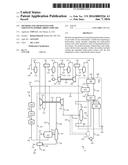

[0011] FIG. 1 is a schematic diagram of an apparatus and method for liquefying hydrocarbon streams in accordance with an embodiment.

DETAILED DESCRIPTION

[0012] The following detailed description is merely exemplary in nature and is not intended to limit the methods and apparatuses for liquefying gas streams claimed herein. Furthermore, there is no intention to be bound by any theory presented in the preceding background or the following detailed description.

[0013] As described herein, methods and apparatuses are provided for liquefying hydrocarbon stream. Shortcomings in convention hydrocarbon liquefying methods and apparatuses may be avoided through embodiments described herein. In an exemplary embodiment, a method cools a hydrocarbon stream to liquid in part by expanding the hydrocarbon stream with a turbo expander. In the exemplary embodiment, energy released from expanding the hydrocarbon stream is used to compress a first refrigerant. The first refrigerant is then cooled in a cooling cascade and is heat exchanged with the hydrocarbon stream to liquefy the hydrocarbon stream. In another embodiment, a second refrigerant is heat exchanged with the first refrigerant to cool the first refrigerant before the heat exchange with the hydrocarbon stream. An exemplary apparatus includes a first refrigerant loop passing through the compression zone of the turbo expander and including a cooling cascade, a second refrigerant loop passing through a first stage in the cooling cascade, and a hydrocarbon stream path passing through the expansion zone of the turbo expander and through a second stage in the cooling cascade. In an exemplary embodiment, the second refrigerant is a mixed refrigerant.

[0014] An understanding of the method and apparatus claimed herein can be obtained by reference to FIG. 1. FIG. 1 has been simplified by the deletion of apparatuses customarily employed in a process of this nature such as vessel internals, temperature and pressure controls systems, flow control valves, recycle pumps, and the like that are not specifically required to illustrate the performance of the method and apparatus.

[0015] In FIG. 1, an apparatus 10 is provided for liquefying a hydrocarbon stream in the gas phase. As shown, the apparatus 10 includes a first refrigerant loop 100, a second refrigerant loop 200, a hydrocarbon stream path 300, and a cold box 400. As used herein, the phrase "cold box" is used as is conventional in the art and refers to an insulated and cooled chamber. An exemplary cold box has dimensions of about 10 feet by 10 feet by 50 feet. Such a chamber may be cooled by a blanket of liquid nitrogen to a temperature range largely un-impacted by changes in the surrounding ambient temperature.

[0016] As shown, the first refrigerant loop 100 holds a first refrigerant 105. In an exemplary embodiment, the first refrigerant 105 is a mixed refrigerant, i.e., a combination of at least two refrigerants. For example, the first refrigerant 105 may include nitrogen, methane, propane and ethane, or other suitable refrigerants. In an exemplary embodiment, the first refrigerant comprises from about 25 wt % to about 35 wt % nitrogen, from about 60 wt % to about 70 wt % methane, from about 2 wt % to about 10 wt % propane, and from about 0.1 wt % to about 3 wt % ethane. An exemplary first refrigerant 105 does not achieve dew point above -55 F, so first refrigerant 105 is not present as a liquid in most of the first refrigerant loop 100. Thus, unit size for compressors and discharge drums may be kept relatively small.

[0017] In the exemplary embodiment, the first refrigerant loop 100 includes a cooling cascade 108 including in series cooling and compressing units. As shown, the first refrigerant 105 enters a compressor suction drum 110 that inhibits further flow of any traces of liquid. Then, the first refrigerant 115 flows into a turbo expander unit 120. Specifically, the first refrigerant 115 flows into a compressor zone 122 of the turbo expander unit 120. The first refrigerant 115 is compressed therein using energy generated by an expansion zone of the turbo expander unit 120, as disclosed below. A compressed first refrigerant 125 exits the turbo expander unit 120 and flows to a compressor discharge cooler 130. At the compressor discharge cooler 130, the first refrigerant 125 is cooled. The cooled first refrigerant 135 is then fed to a compressor suction drum 140.

[0018] Then, the first refrigerant 145 flows to a compressor 150. Specifically, the first refrigerant 145 is delivered to a first stage 152 of a compressor 150. The further compressed first refrigerant 155 is then received by an interstage compressor discharge cooler 160 wherein the first refrigerant 155 is further cooled. As shown, the first refrigerant 165 exits the interstage cooler 160 and is delivered to a compressor suction drum 170. The first refrigerant 175 exits the compressor suction drum 170 and is fed to a second stage 180 of the compressor 150. As shown, the second stage 180 and first stage 152 of the compressor 150 are mechanically connected by compressor drive shaft 182. Further, a compressor driver 184 is mechanically connected to the compressor drive shaft 182, first stage 152 and second stage 180 to drive compression of the first refrigerant therein. An exemplary compressor 150 is a two-stage centrifugal compressor designed with dry-gas seals to avoid contamination of the circulating first refrigerant (145, 155, 175, 185). Because the first refrigerant attains temperatures as low as about -168° C. (-270° F.), the lube oil should not be allowed to contaminate the refrigerant. The driver 184 for the compressor 150 may be gas turbine or electric, when available. Any make-up refrigerant may be provided by onsite nitrogen and propane tanks.

[0019] The compressed refrigerant 185 exits the second stage 180 of the compressor 150 and is fed to a compressor discharge cooler 190. The first refrigerant 195 is fed from the compressor discharge cooler 190 to a compressor suction drum 198. As shown, the first refrigerant 199 is provided by the compressor suction drum 198 to the cold box 400. In an exemplary embodiment, the first refrigerant 199 is cooled to a temperature of below about 50° C. (120° F.), such as below about 43° C. (110° F.). Further, in an exemplary embodiment, the first refrigerant 199 is pressurized to from about 35 bar (500 psi) to about 41 bar (600 psi), such as to about 38 bar (550 psi).

[0020] As shown, cold box 400 holds a cooling cascade 402 including a plurality of cooling stages. The first refrigerant 199 enters a first stage 405 where the first refrigerant 199 is cooled via heat exchange. In an exemplary embodiment, the first refrigerant 410 is cooled to the approximate dew point of the first refrigerant 410. For example, the first refrigerant 410 is cooled to about -22° C. (-8° F.). The first refrigerant 410 is then fed to a second stage 415 where it is further cooled by heat exchange. For example, the first refrigerant 420 is cooled to less than about -50° C. (-60° F.), such as to about -56° C. (-70° F.). A temperature control on the external refrigeration feed controls this temperature within the cold box. The first refrigerant 420 then enters a third stage 425 where the first refrigerant 420 is cooled further. In an exemplary embodiment, the third stage 425 completely liquefies and subcools the first refrigerant 430.

[0021] After the first refrigerant 430 is completely liquefied, the first refrigerant 430 exits the cold box 400 and is fed to an evaporator valve 435. At the evaporator valve 435, the depressured refrigerant partially flashes, where the latent heat of vaporization cools the refrigerant to less than about -160° C. (-255° F.), such as to about -163° C. (-262° F.). The cold low pressure first refrigerant 440 then returns to the cold box 400 and enters the fourth stage 445. At the fourth stage 445, the first refrigerant 440 cools the hydrocarbon stream, as discussed below, to form a liquid hydrocarbon.

[0022] The first refrigerant 450 begins exiting the cooling cascade 402 by flowing through the third stage 425. The first refrigerant 450 cools, and is heated by, the first refrigerant 420. The first refrigerant 455 then exits the third stage 425 and enters the first stage 405. At the first stage 405, the exiting first refrigerant 455 cools the entering first refrigerant 199. The first refrigerant 460 then exits the cold box 400 and is returned as first refrigerant 105 to the cooling cascade 108.

[0023] The first refrigerant loop 100 provides for economic cooling of the first refrigerant 105 through cooling cascade 102 using the compressor 150, through the cooling cascade 402 in the cold box 400, and through use of the expansion valve 435. Only in the cold box 400 and expansion valve 435 is the first refrigerant processed as a liquid. Thus processing unit size upstream of the cold box 400 is minimized and costs reduced. Any make-up first refrigerant may be provided by onsite nitrogen and propane tanks.

[0024] In the second refrigerant loop 200, a second refrigerant 205 is circulated as described. As shown, a portion 210 of the second refrigerant 205 passes through a chiller 215 where it cools an incoming hydrocarbon stream as described below. The portion 220 of the second refrigerant exits the chiller 215 and is recirculated back into the second refrigerant loop 200. A portion 225 of the incoming second refrigerant 205 is fed to the second stage 415 of the cooling cascade 402 in the cold box 400. At the second stage 415, the portion 225 of the second refrigerant cools the first refrigerant 410 as described above.

[0025] The portion 230 of the second refrigerant exiting the second stage 415 is then combined with the portion 220 to form recirculating second refrigerant 235. The second refrigerant 235 is then re-cooled before being split and delivered to the chiller 215 and second stage 415. Specifically, the second refrigerant 235 enters a knockout drum 240 where condensed contaminants may be removed. The second refrigerant stream 245 exits the knockout drum 240 and enters a compressor suction drum 250. From the compressor suction drum 250, the second refrigerant 255 is fed to an air cooler 260 or other suitable cooling unit. Cooler 260 brings the second refrigerant 205 to a desired temperature for use in the apparatus 10. For example, the second refrigerant 205 may attain a temperature of less than about -56° C. (-70° F.), such as about -59° C. (-75° F.). An exemplary second refrigerant 205 is a mixture of propane and ethane.

[0026] Interaction of the hydrocarbon stream path 300 and the first refrigerant loop 100 and second refrigerant loop 200 is now addressed. As shown, the hydrocarbon feed stream 305 is fed through and cooled by a heat exchanger 310. An exemplary hydrocarbon feed stream is rich in natural gas, though any suitable stream for which liquefaction is desired may be used. The exemplary hydrocarbon feed stream 305 enters the apparatus 10 at a pressure of from about 55 bar (800 psi) to about 69 bar (1000 psi). The cooled hydrocarbon stream 315 exits the heat exchanger and is fed to chiller 315 where the hydrocarbon stream 315 is further cooled by the second refrigerant 210. In an exemplary embodiment, the chiller 315 cools the hydrocarbon stream 320 to less than about -50° C. (-60° F.), such as to about -56° C. (-70° F.). At about -34° C. (-30° F.), feed contaminants such as heavies, mercaptans, pipeline compressor lube oil, or the like are removed at a knockout drum 325. The knockout drum 325 forms a stream 330 of contaminants that is used to cool the incoming hydrocarbon feed stream 305 at heat exchanger 310.

[0027] As shown, the hydrocarbon stream 340 exits the knockout drum 325 and is fed to the turbo expander 120. Specifically, the hydrocarbon stream 340 passes through an expansion zone 345 of the turbo expander 120. The hydrocarbon stream 340 is expanded through the expansion zone 345 and drops in pressure to at least about 1.7 bar (25 psi), such as to about 3.4 bar (50 psi). Energy generated by expansion of the hydrocarbon stream 340 in the expansion zone 345 is used to drive compression of the first refrigerant 115 in the compression zone 122 of the turbo expander 120 through mechanical connection of the drive shaft 355. A mixed phase hydrocarbon stream 350 exits the turbo expander 120 at a temperature of less than about -125° C. (-200° F.), such as about -137° (-215° F.).

[0028] The mixed phase hydrocarbon stream 350 is delivered to the cold box 400. Specifically, the mixed phase hydrocarbon stream 350 enters a separator 470. Separator 470 forms a vapor stream 475 and a liquid stream 480. Each stream 475 and 480 may exit the cold box 400 and pass through external control valves (not shown). Then, each stream 475 and 480 are fed through separate nozzles to the fourth stage 445 of the cooling cascade 402. An exemplary fourth stage 445 is a brazed aluminum exchanger. At the fourth stage 445, the hydrocarbon stream 480 is cooled by the first refrigerant 440 to less than about -157° C. (-250° F.), such as to about -161° C. (-258° F.). At this temperature, remaining vapors within the hydrocarbon stream 490 are condensed and sub-cooled slightly before exiting the cold box 400 and being sent to chilled tankage.

[0029] For startup, the hydrocarbon stream 350 may be directed as stream 360 to a heat exchanger 365 for cooling by the first refrigerant 430 prior to entering the cold box 400. The cooled hydrocarbon stream 370 is then delivered to the separator 470 and processed as described above.

[0030] As described herein, an exemplary method and apparatus are provided for liquefying a hydrocarbon stream. The exemplary method and apparatus utilize turbo expander technology to remove energy from the high pressure hydrocarbon stream and to use the energy to compress a first refrigerant for cooling thereof. The first refrigerant is cooled in a cooling cascade before being expanded to reach a temperature suitable for liquefying the hydrocarbon stream through heat exchange. The integration of a first refrigerant loop, second refrigerant loop and hydrocarbon gas path provide for reduced costs in processing the respective streams. Further, use of a cold box to house the first refrigerant cooling cascade while withdrawing heat from the cold box with the second refrigerant reduces costs in liquefying the hydrocarbon stream.

[0031] While at least one exemplary embodiment has been presented in the foregoing detailed description, it should be appreciated that a vast number of variations exist. It should also be appreciated that the exemplary embodiment or exemplary embodiments are only examples, and are not intended to limit the scope, applicability, or configuration of the claimed subject matter in any way. Rather, the foregoing detailed description will provide those skilled in the art with a convenient road map for implementing an exemplary embodiment or embodiments. It being understood that various changes may be made in the function and arrangement of elements described in an exemplary embodiment without departing from the scope set forth in the appended claims.

User Contributions:

Comment about this patent or add new information about this topic:

| People who visited this patent also read: | |

| Patent application number | Title |

|---|---|

| 20200034239 | METHOD AND APPARATUS FOR DETECTING AND REMEDYING SINGLE EVENT EFFECTS |

| 20200034238 | Method and Device for File Storage |

| 20200034237 | MANAGING BOOT FAILURES IN AN INFORMATOIN HANDLING SYSTEM |

| 20200034236 | DYNAMIC TRANSACTION THROTTLING IN A DATA PROCESSING SYSTEM SUPPORTING TRANSACTIONAL MEMORY |

| 20200034235 | MANAGING MAPPED RAID EXTENTS IN DATA STORAGE SYSTEMS |