Patent application title: PROTECTION DEVICE FOR AN ELECTRONIC DEVICE

Inventors:

Ming-Chang Lee (New Taipei, TW)

Ming-Chang Lee (New Taipei, TW)

Hai Liu (Shenzhen, CN)

Hai Liu (Shenzhen, CN)

Hong-Liang Pu (Shenzhen, CN)

IPC8 Class: AA45C1100FI

USPC Class:

224577

Class name: Carried by animate bearer convertible or combined convertible to a different art device

Publication date: 2015-10-29

Patent application number: 20150305459

Abstract:

A protection device includes a receiving portion for receiving an

electronic device and a cover portion pivotally connected to one side of

the receiving portion for opening or covering the receiving portion. The

cover portion includes a first reinforcing member, two right angle

trapezoid-shaped second reinforcing members symmetrically located at two

opposite sides of the first reinforcing member, two third reinforcing

members, and a fourth reinforcing member. The two third reinforcing

members respectively located between the two second reinforcing members

and the fourth reinforcing member. The first, second, third and fourth

reinforcing members are connected flexibly to each other. When the first

reinforcing member is folded relative to the fourth reinforcing member

and the second reinforcing members contact the first reinforcing member,

the cover portion is rotated to allow the first reinforcing member to

abut against a back of the receiving portion.Claims:

1. A protection device comprising: a receiving portion for receiving an

electronic device therein; and a cover portion pivotally connected to the

receiving portion to cover the electronic device, the cover portion

comprising a first reinforcing member, two right angle trapezoid-shaped

second reinforcing members symmetrically positioned on opposite sides of

the first reinforcing member, two third reinforcing members, and a fourth

reinforcing member; wherein the two third reinforcing members are

respectively located between the two second reinforcing members and the

fourth reinforcing member, the first, second, third and fourth

reinforcing members are foldably connected to each other by fold lines

between the reinforcing members; and wherein the first reinforcing member

is folded relative to the fourth reinforcing member and the two second

reinforcing members are folded toward the first reinforcing member, the

two third reinforcing members are folded to a position between the first

reinforcing member and the fourth reinforcing member, the cover portion

is rotated to allow the first reinforcing member to abut against a back

of the receiving portion.

2. The protection device of claim 1, wherein the receiving portion comprises a base plate and peripheral edges extending from edges of the base plate, the base plate and the peripheral edges defining a receiving space for holding the electronic device.

3. The protection device of claim 1, wherein the cover portion is connected to the receiving portion by a flexible rubber strip.

4. The protection device of claim 1, wherein the first reinforcing member is rectangular and comprises a pair of first sides and a pair of second sides perpendicular to the first sides, one first side of the first reinforcing member is located at a middle of a side of the cover portion away from the flexible rubber strip, the fourth reinforcing member is isosceles trapezoid and comprises a first base and a second base parallel to the first base and longer than the first base, the second base of the fourth reinforcing member is located at a side of the cover portion adjacent to the flexible rubber strip, the first base of the fourth reinforcing member is adjacent and parallel to one first side of the first reinforcing member.

5. The protection device of claim 4, wherein each third reinforcing member is isosceles triangle.

6. The protection device of claim 5, wherein each second reinforcing member comprises a first base, a second base parallel to the first base and longer than the first base, a first side perpendicularly connected between the first base and the second base, and a second side angularly connected between the first base and the second base, the first and second bases of the two second reinforcing members are respectively adjacent and parallel to the second sides of the first reinforcing member, a pair of sides of each third reinforcing member are adjacent to the second side of the corresponding second reinforcing member and the side of the fourth reinforcing member.

7. The protection device of claim 1, wherein the first reinforcing member and the two second reinforcing members comprise a plurality of magnets embedded therein for attracting the first reinforcing member and the second reinforcing members.

8. The protection device of claim 1, wherein the first, second, third and fourth reinforcing members are made of rigid boards.

9. The protection device of claim 1, wherein the first, second, third and fourth reinforcing members are encapsulated between a first surface layer and a second surface layer of cover portion, the first surface layer is an outer surface of the cover portion, and the second surface layer is an inner surface of the cover portion, in areas between the reinforcing members, the first surface layer and the second surface layer are connected together to form fold lines between the first reinforcing member, the second reinforcing members, the third reinforcing members, and the fourth reinforcing member.

10. A cover comprising: a first reinforcing member, two right angle trapezoid-shaped second reinforcing members symmetrically located at two opposite sides of the first reinforcing member, two third reinforcing members, and a fourth reinforcing member; wherein the two third reinforcing members are respectively located between the two second reinforcing members and the fourth reinforcing member, the first, second, third and fourth reinforcing members are foldably connected to each other; and wherein the first reinforcing member is folded out relative to the fourth reinforcing member and the two second reinforcing members contact an outer surface of the first reinforcing member.

11. The cover of claim 10, wherein the first reinforcing member is rectangular and comprises a pair of first sides and a pair of second sides perpendicular to the first sides, the fourth reinforcing member is isosceles trapezoid and comprises a first base and a second base parallel to the first base and longer than the first base, the first base of the fourth reinforcing member is adjacent and parallel to one first side of the first reinforcing member.

12. The cover of claim 10, wherein the third reinforcing member is an isosceles triangle.

13. The cover of claim 12, wherein each second reinforcing member comprises a first base, a second base parallel to the first base and longer than the first base, a first side perpendicularly connected between the first base and the second base, and a second side angularly connected between the first base and the second base, the first and second bases of the two second reinforcing members are respectively adjacent and parallel to the second sides of the first reinforcing member, a pair of sides of each third reinforcing member are adjacent the second side of the corresponding second reinforcing member and the side of the fourth reinforcing member.

14. The cover of claim 10, wherein the first, second, third and fourth reinforcing members are made of rigid boards.

15. The cover of claim 10, wherein the first, second, third and fourth reinforcing members are encapsulated between a first surface layer and a second surface layer of cover portion, the first surface layer is an outer surface of the cover portion, and the second surface layer is an inner surface of the cover portion, in areas between the reinforcing members, the first surface layer and the second surface layer are connected together to form fold lines between the first reinforcing member, the second reinforcing members, the third reinforcing members, and the fourth reinforcing member.

16. The cover of claim 10, wherein the first reinforcing member and the two second reinforcing members comprise a plurality of magnets embedded therein for attracting the first reinforcing member and the second reinforcing members.

Description:

FIELD

[0001] The subject matter herein generally relates to a protection device for an electronic device.

BACKGROUND

[0002] Electronic devices are often used with a protection device to protect the device from damage or shock. The protection device can be a single case or a complex cover.

BRIEF DESCRIPTION OF THE DRAWINGS

[0003] Implementations of the present technology will now be described, by way of example only, with reference to the figures.

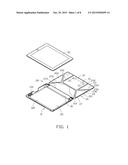

[0004] FIG. 1 is an isometric view of an embodiment of a protection device and an electronic device, wherein the protection device includes a receiving portion and a cover portion.

[0005] FIG. 2 is an assembled, isometric view of FIG. 1, showing the cover portion covering the receiving portion.

[0006] FIG. 3 is a cross-sectional view along line III-III of FIG. 1.

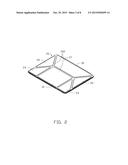

[0007] FIG. 4 is an isometric view of the cover portion of FIG. 1, showing the cover portion folded along fold lines.

[0008] FIG. 5 is an assembled, isometric view of FIG. 1, showing the cover portion folded along fold lines to support the receiving portion in a first configuration.

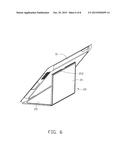

[0009] FIG. 6 is similar to FIG. 5, but viewed from another aspect, showing the cover portion folded along fold lines and supporting the receiving portion in a first configuration.

[0010] FIG. 7 is similar to FIG. 6, but viewed from another aspect, showing the cover portion folded along fold lines and supporting the receiving portion in a first configuration.

[0011] FIG. 8 is similar to FIG. 5, showing the cover portion folded along fold lines and supporting the receiving portion in a second configuration.

DETAILED DESCRIPTION

[0012] It will be appreciated that for simplicity and clarity of illustration, where appropriate, reference numerals have been repeated among the different figures to indicate corresponding or analogous elements. In addition, numerous specific details are set forth in order to provide a thorough understanding of the embodiments described herein. However, it will be understood by those of ordinary skill in the art that the embodiment described herein can be practiced without these specific details. In other instances, methods, procedures and components have not been described in detail so as not to obscure the related relevant feature being described. Also, the description is not to be considered as limiting the scope of the embodiments described herein. The drawings are not necessarily to scale and the proportions of certain parts have been exaggerated to better illustrate details and features of the present disclosure.

[0013] Several definitions that apply throughout this disclosure will now be presented.

[0014] The term "substantially" is defined to be essentially conforming to the particular dimension, shape or other word that substantially modifies, such that the component need not be exact. For example, substantially cylindrical means that the object resembles a cylinder, but can have one or more deviations from a true cylinder. The term "comprising," when utilized, means "including, but not necessarily limited to"; it specifically indicates open-ended inclusion or membership in the so-described combination, group, series and the like.

[0015] The present disclosure describes a protection device 100 for holding and supporting an electronic device 50.

[0016] FIG. 1 illustrates an embodiment of the protection device 100. The protection device 100 includes a receiving portion 10 and a cover portion 20 pivotally connected to the receiving portion 10. In this embodiment, the cover portion 20 is pivotally connected to the receiving portion 10 by a flexible rubber strip 30.

[0017] The receiving portion 10 includes a substantially rectangular base plate 101 and a peripheral edge 103 extending from edges of the base plate 101. The base plate 101 and the peripheral edge 103 define a receiving space 105 for holding the electronic device 50. In the embodiment, the electronic device 50 is a handheld device, such as a mobile phone. A first edge of the flexible rubber strip 30 is fixed to the base plate 101. A second edge of the flexible rubber strip 30, opposite and parallel to the first edge, is connected to the cover portion 20. In this embodiment, the receiving portion 10 is a hard shell, made of, for example, plastic, carbon fiber or glass fiber.

[0018] FIGS. 2 and 3 illustrate that the cover portion 20 is substantially rectangular and comprises a substantially rectangular-shaped first reinforcing member 21, two right angle trapezoid-shaped second reinforcing members 23, symmetrically positioned on opposite sides of the first reinforcing member 21, two isosceles triangle-shaped third reinforcing members 25 also positioned on opposite sides of the first reinforcing member 21, and an isosceles trapezoid-shaped fourth reinforcing member 27 is positioned adjacent a side of the rectangular-shaped perpendicular to the first reinforcing member 21. Each of the first reinforcing member 21, the second reinforcing members 23, the third reinforcing members 25, and the fourth reinforcing member 27 comprise a rigid board encapsulated between a first surface layer 201 and a second surface layer 203 of cover portion 20. The first surface layer 201 is an outer surface of the cover portion 20, formed of, for example, leather, and the second surface layer 203 is an inner surface of the cover portion 20, formed of, for example, superfine fiber layer. In areas positioned between reinforcing members, the first surface layer 201 and the second surface layer 203 are connected together to form fold lines 202 in the areas between the first reinforcing member 21, the second reinforcing members 23, the third reinforcing members 25, and the fourth reinforcing member 27. The rigid boards of each of the first reinforcing member 21, the second reinforcing member 23, the third reinforcing member 25, and the fourth reinforcing member 27 may comprises rigid board materials, such as such as fiberglass, carbon fiber board, cardboard or plastic board. As shown in FIGS. 1 and 3, each of the first reinforcing member 21 and the second reinforcing members 23 comprise a plurality of embedded magnets 70. When the two second reinforcing members 23 are folded to attach the first reinforcing member 21, the magnet 70 of each second reinforcing member 23 is attracted to one of the two magnets 70 of the first reinforcing member 21.

[0019] Returning to FIG. 1, the first reinforcing member 21 comprises a pair of parallel first sides 210 and a pair of parallel second sides 212. The first sides 210 are perpendicular to the second sides 212. One first side 210 of the first reinforcing member 21 is located at a middle of a side of the cover portion 20 away from the flexible rubber strip 30. The fourth reinforcing member 27 comprises a first base 270, a second base 272 parallel to the first base 270 and longer than the first base 270, and a pair of non-parallel sides slantingly connected between the first base 270 and the second base 272. Each second reinforcing member 23 comprises a first base 230, a second base 232 parallel to the first base 230 and longer than the first base 230, and a first side 234 perpendicularly connected between the first base 230 and the second base 232, and a second side 236 slantingly connected between the first base 230 and the second base 232.

[0020] The second base 272 of the fourth reinforcing member 27 is adjacent to the flexible rubber strip 30. One of the first sides 210 of the first reinforcing member 21 is adjacent the first base 270 of the fourth reinforcing portion 27. The other first sides 210 of the first reinforcing member 21 and the first sides 234 of the second reinforcing members 23 lie along a straight line. The third reinforcing members 25 are respectively located between the second side 236 of two second reinforcing members 23 and the sides of the fourth reinforcing member 27. The second bases 232 of the second reinforcing members 23 are respectively beside the second sides 212 of the first reinforcing member 21. The first base 230 of each second reinforcing member 23 and the base of the corresponding third reinforcing member 25 lie along a straight line.

[0021] The electronic device 50 is held in the receiving space 105 of the receiving portion 10, and the cover portion 20 can be rotated to cover the receiving portion 10 to protect the electronic device 50.

[0022] FIGS. 4 to 7 illustrate the cover portion 20 folded in a first configuration. The first reinforcing member 21 is rotated relative to the fourth reinforcing member 27 toward the first surface layer 201 of the cover 10, the two second reinforcing members 23 are folded along fold lines to contact an outer surface of the first reinforcing member 21 and the second reinforcing members 23 are attracted to the first reinforcing member 21 by the magnets 70 embedded therein, the two third reinforcing members 25 are folded along fold lines to a position between the first reinforcing member 21 and the fourth reinforcing member 27 (shown in FIG. 6). The folded cover portion 20 is rotated toward the receiving portion 10. A perimeter edge of the first side 210 of the first reinforcing member 21 away from the fourth reinforcing member 27 catches a back of the receiving portion 10 to support the receiving portion 10 with the electronic device 50 being received in the receiving portion 10. The fourth reinforcing member 27 and a side of the receiving portion 10 adjacent to the flexible rubber strip 30 are supported on a supporting plane, such as a desk. In this embodiment, an angle between the receiving portion 10 and the supporting plane is approximately 60 degrees.

[0023] FIG. 8 illustrates the electronic device 50 when supported by the cover portion 20 folded in a second configuration. The two second reinforcing members 23 are folded along fold lines to contact an outer surface of the first reinforcing member 21 and the second reinforcing members 23 are attracted to the first reinforcing member 21 by the magnets 70 embedded therein, the two third reinforcing members 25 are folded along fold lines to a position between the first reinforcing member 21 and the fourth reinforcing member 27. The fold line 202 between the first reinforcing member 21 and the fourth reinforcing member 27, and a side of the receiving portion 10 away from the flexible rubber strip 30 can be supported on the supporting plane. In this configuration the angle between receiving portion 10 and the supporting plane is approximately 20 degrees.

[0024] The receiving portion 10 of the protection device 100 can hold the electronic device 50 and the cover portion 20 can be rotated to cover the receiving portion 10 and protect the electronic device 50. And the cover portion 20 can also be folded along fold lines in two different ways to support the electronic device at different angles.

[0025] It is to be understood, however, that even though numerous characteristics and advantages of the embodiments have been set forth in the foregoing description, together with details of the structure and function of the embodiments, the disclosure is illustrative only, and changes may be made in detail, especially in the matters of shape, size, and arrangement of parts within the principles of the disclosure to the full extent indicated by the broad general meaning of the terms in which the appended claims are expressed.

User Contributions:

Comment about this patent or add new information about this topic: