Patent application title: AUGER FOR GAS AND LIQUID RECOVERY FROM REGOLITH

Inventors:

Andrew J. Zillmer (West Hills, CA, US)

Cheng-Yi Lu (West Hills, CA, US)

Cheng-Yi Lu (West Hills, CA, US)

Assignees:

HAMILTON SUNDSTRAND CORPORATION

IPC8 Class: AE21B4324FI

USPC Class:

1662721

Class name: Processes distinct, separate injection and producing wells involving the step of heating

Publication date: 2012-06-21

Patent application number: 20120152537

Abstract:

A resource recovery system includes a capture container located at a

desired surface defining a capture volume between the surface and an

interior of the capture container. One or more hole-making devices are

located in the capture container to excavate soil from at least one hole

in the surface. A heater located in the hole making device heats the

excavated soil, releasing one or more compounds from the excavated soil.

The capture container is configured to capture gas and/or liquid

compounds released from the excavated soil. A method of resource

extraction from soil includes covering a desired surface with a capture

container defining a capture volume between the desired surface and an

interior of the capture container. Soil is excavated from a hole in the

desired surface into the capture volume with an auger. The auger heats

the excavated soil thereby releasing one or more compounds into the

capture volume.Claims:

1. A resource recovery system comprising: a capture container defining a

capture volume between a surface and an interior of the capture

container; one or more hole-making devices disposed in the capture

container configured to excavate soil from at least one hole in the

surface; and a heater disposed in the hole making device configured to

heat the hole making device, thereby heating the excavated soil to

release one or more compounds from the excavated soil; wherein the

capture container is configured to capture gas and/or liquid compounds

released from the excavated soil.

2. The system of claim 1, wherein the one or more hole-making devices are one or more augers.

3. The system of claim 2, wherein the one or more augers comprise: a central rod; and one or more fins extending from the central rod; wherein the heater is disposed in a rod channel of the central rod.

4. The system of claim 3, wherein the one or more fins include one or more fin channels connected to the rod channel.

5. The system of claim 1, wherein the one or more hole making devices are one or more spikes, rods, or impactors.

6. The system of claim 1, wherein the heater is a radioisotope heater or an electric heater.

7. The system of claim 1, further comprising a collection device to remove the compounds from the capture container.

8. The system of claim 7, wherein the collection device is one of a cold plate, a still, or a turbopump.

9. The system of claim 1, wherein the compounds are in liquid or gaseous form.

10. The system of claim 1, wherein the surface comprises regolith.

11. The system of claim 1, wherein the system is secured to a movable cart.

12. A method of resource extraction from soil comprising: covering a desired surface with a capture container defining a capture volume between the desired surface and an interior of the capture container; excavating soil from a hole in the desired surface into the capture volume with an auger; and heating the excavated soil with the auger thereby releasing one or more compounds into the capture volume.

13. The method of claim 12, wherein the auger comprises: a central rod; one or more fins extending from the central rod; and a heater disposed in a rod channel of the central rod to heat the auger thereby heating the excavated soil.

14. The method of claim 13, wherein the one or more fins include one or more fin channels connected to the rod channel.

15. The method of claim 12, wherein the heater is a radioisotope heater or an electric heater.

16. The method of claim 12, further comprising removing the compounds from the capture volume via a collection device.

17. The method of claim 16, wherein the collection device is one of a cold plate, a still, or a turbopump.

18. The method of claim 12, wherein the compounds are in liquid or gaseous form.

19. An auger for soil excavation comprising: a central rod; one or more fins extending from the central rod; and a heater disposed in a rod channel of the central rod to heat the auger thereby heating the soil.

20. The auger of claim 19, wherein the one or more fins include one or more fin channels connected to the rod channel.

21. The auger of claim 19, wherein the heater is a radioisotope heater or an electric heater.

Description:

BACKGROUND OF THE INVENTION

[0001] The subject matter disclosed herein relates to resource recovery. More specifically, the subject disclosure relates gas and liquid resource recovery from regolith.

[0002] Regolith is a layer of loose, heterogeneous material covering solid rock. It includes dust, soil, broken rock, and other related materials and is present on Earth, the Moon, some asteroids, and other planets. Transportation of fuel and other resources to locations such as the Moon for use on the Moon and/or for a return trip to Earth adds mass and complexity to the craft carrying the resources and the mission in general which much address storage and handling of the resources. Systems and methods to extract gas and/or liquid resources from a regolith surface of, for example, the Moon, for use on site would be desired to enable faster missions or to enable more equipment to be transported on the mission in place of the fuel or other resources that would ordinarily be transported.

BRIEF DESCRIPTION OF THE INVENTION

[0003] According to one aspect of the invention, a resource recovery system includes a capture container defining a capture volume between a desired surface and an interior of the capture container. One or more hole-making devices are located in the capture container to excavate soil from at least one hole in the desired surface. A heater is located in the hole making device to the heat hole making device, thereby heating the excavated soil to release one or more compounds from the excavated soil. The capture container is configured to capture gas and/or liquid compounds released from the excavated soil.

[0004] According to another aspect of the invention, a method of resource extraction from soil includes covering a desired surface with a capture container defining a capture volume between the desired surface and an interior of the capture container. Soil is excavated from a hole in the desired surface into the capture volume with an auger. The auger is utilized to heat the excavated soil thereby releasing one or more compounds into the capture volume.

[0005] According to yet another aspect of the invention, an auger for soil excavation includes a central rod and one or more fins extending from the central rod. A heater is located in a rod channel of the central rod to heat the auger thereby heating the soil.

[0006] These and other advantages and features will become more apparent from the following description taken in conjunction with the drawings.

BRIEF DESCRIPTION OF THE DRAWINGS

[0007] The subject matter, which is regarded as the invention, is particularly pointed out and distinctly claimed in the claims at the conclusion of the specification. The foregoing and other features, and advantages of the invention are apparent from the following detailed description taken in conjunction with the accompanying drawings in which:

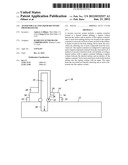

[0008] FIG. 1 is a schematic view of an embodiment of a resource recovery system;

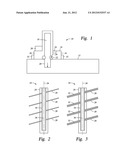

[0009] FIG. 2 is a schematic view of an embodiment of an auger for a resource recovery system; and

[0010] FIG. 3 is a schematic view of another embodiment of an auger for a resource recovery system.

[0011] The detailed description explains embodiments of the invention, together with advantages and features, by way of example with reference to the drawings.

DETAILED DESCRIPTION OF THE INVENTION

[0012] Shown in FIG. 1 is an embodiment of a resource recovery system 10. The system 10 is located at a desired regolith surface 12, such as on Earth, the Moon, an asteroid, or another planet. A capture container 14 is placed over the surface 12 to be scavenged for resources defining a capture volume 30 between the surface 12 and an interior of the capture container 14. In some embodiments, the capture container 14 is fitted to the surface 12, either through flexibility of the container 14 or other means, such as a seal, to control leakage of recovered resources from an interior 16 of the capture container 14.

[0013] One or more hole making devices 18, such as, for example, an auger, spike, rod or impactor other hole-making device, is located in the interior of the capture container 14. While only one hole making device 18 is shown in FIG. 1, it is to be appreciated that other quantities of hole making devices 18, for example 2, 3, or 4 or more hole making devices 18 may be utilized to increase a rate of resource recovery into the capture container 14. The hole making device 18 is utilized to make a hole 20 in the surface 12 and pull excavated soil 22 from the hole 20 to the surface 12. Referring now to FIG. 2, an exemplary hole making device 18, an auger, includes a rod 24, which in some embodiments is located along a central axis 26 of the auger 18. The rod 24 is a substantially hollow, tubular structure. One or more fins 28 extend outwardly from the rod 24, which in some embodiments are arranged helically around the rod 24. As shown in FIG. 3, the fins 28 may be substantially hollow or have a fin channel 32 connected to a rod channel 34. A heater 36 is disposed in the rod channel 34 and/or the fin channel 32. The heater 36 may be, for example, a radioisotope heater or an electric heater. The heater 36 is configured such that, when activated, it heats the rod 24 and/or the fins 28 of the auger 18. This in turn heats the soil 22 excavated by the auger 18. While the heater 36 is shown inserted into an auger, it is to be appreciated that the heater 36 may similarly be inserted into any other hole making device 18.

[0014] Referring again to FIG. 1, heating of the excavated soil 22 releases desirable resources and/or compounds in the excavated soil 22 in the form of gases and/or liquids into the capture container 14. To compliment the heating of the soil 22 via the hole making device 18, one or more energy emitters 38 may be located in the capture container 14 to further heat the soil 22. The emitters 38 may be, for example, microwave emitters or concentrated solar energy emitters. The resources are removed from the capture container 14 by a collection device 40 for further processing as necessary. The collection device 40 may be, for example, a cold plate, still, turbopump, or other collection device 40. Further, in some embodiments, the system 10 is disposed on a moveable structure, for example a cart 42, so that when resource scavenging is completed at one site, the system 10 is easily movable to a second site for additional resource scavenging and recovery.

[0015] While the invention has been described in detail in connection with only a limited number of embodiments, it should be readily understood that the invention is not limited to such disclosed embodiments. Rather, the invention can be modified to incorporate any number of variations, alterations, substitutions or equivalent arrangements not heretofore described, but which are commensurate with the spirit and scope of the invention. Additionally, while various embodiments of the invention have been described, it is to be understood that aspects of the invention may include only some of the described embodiments. Accordingly, the invention is not to be seen as limited by the foregoing description, but is only limited by the scope of the appended claims.

User Contributions:

Comment about this patent or add new information about this topic: