Patent application title: METHOD FOR THE TRANSPORT, HANDLING, POSITIONING AND FIXING OF FLOOR-TO-CEILING PREFABRICATED CONSTRUCTION ELEMENT'S TO FORM FIRE-RESISTANT INTERNAL WALLS OR PARTIITIONS IN CONSTRUCTIONS OF ANY TYPE, INCLUDING NAVAL CONSTRUCTION

Inventors:

Salvador Mateu Climent (Valencia, ES)

IPC8 Class: AE04G2116FI

USPC Class:

5274513

Class name: Processes barrier construction using prefabricated unit

Publication date: 2011-10-06

Patent application number: 20110239583

Abstract:

The present invention relates to a method for the transport, handling,

positioning and fixing of floor-to-ceiling prefabricated construction

elements to form fire-resistant internal walls or partitions in

constructions of any type, including naval construction, comprising the

transfer and positioning of each panel (10) by means of transfer truck

(1), optionally provided for panels (10) of more than 50 kg with an

extendable rotary crane (3) holding them; the placement of a bolt (11)

fixed to the ceiling and a sleeve (13) having an internal thread, and on

the floor (S) a concrete bedplate (12), fixed by means of screws (18),

incorporating in the upper edge of the panel (10) a metal bracket (20)

having an inverted U section, fitted to the sleeve (13), and filling the

space (14) existing between the panel (10) and the ceiling with concrete.Claims:

1. A method for the transport, handling, positioning and fixing of

floor-to-ceiling prefabricated construction elements to form

fire-resistant internal walls or partitions in constructions of any type,

including naval construction, of the type using a transfer truck and

fixing the elements by means of screws fixed to the ceiling and supported

on concrete elements on the floor, characterized by comprising using a

transfer truck or structure (1), optionally provided with an extendable

rotary crane (3) (in the event that the panels (10) or elements to be

handled have a heavy weight, for example more than 50 kg) and provided

with means for holding the panels (10) or construction elements to be

handled, whereby performing, as a first step of the method, the transfer

and positioning of each panel (10); in that for fixing the element (10),

there is provided the placement of a screw or bolt (11) fixed to the

ceiling (T) to which there is incorporated, on the part thereof that is

external to the ceiling, a sleeve (13) having an internal thread, and on

the floor (S) the placement of a bedplate (12), preferably of concrete,

fixed by means of screws (18) inserted through vertical holes (15)

provided for such purpose; in that once the screw (11) of the ceiling and

the bedplate (12) of the floor are placed, the panel (10) or construction

element is positioned between them, in the upper edge of which there is

incorporated a metal bracket (20) having an inverted U section, said

bracket (20) being fitted by means of pressure to the sleeve (13)

covering the bolt (11) located in the ceiling; and finally in that the

space (14) existing between the panel (10) and the ceiling, and

corresponding to the space occupied by the sleeve (13), is filled with

concrete.

2. The method for the transport, handling, positioning and fixing of floor-to-ceiling prefabricated construction elements to form fire-resistant internal walls or partitions in constructions of any type, including naval construction, according to claim 1, characterized by the transfer truck or structure (1) being provided with a front support base for incorporating the panels (10) or elements to be transported, and with wheels (21) which can be manually operated by human or mechanical thrust or by a combination of both systems, as well as with an articulated mechanism which allows extending and retracting supplementary support feet (5).

3. The method for the transport, handling, positioning and fixing of floor-to-ceiling prefabricated construction elements to form fire-resistant internal walls or partitions in constructions of any type, including naval construction, according to claim 1, characterized by the crane (3) provided on the transfer truck or structure (1) in the event that the panels (10) or elements to be handled have a heavy weight, for example more than 50 kg, being extendable and rotary, for which purpose it is provided with telescopic prolongations (8); and in that it has a hanging hook (6) and a retaining bolt or pin (7) intended for holding the panel (10).

4. The method for the transport, handling, positioning and fixing of floor-to-ceiling prefabricated construction elements to form fire-resistant internal walls or partitions in constructions of any type, including naval construction, according to claim 1, characterized by the bedplate (12) being provided with through holes (16) traversing it longitudinally, intended for the electrical installation; and in that it has at least one access opening (17) in its central area.

Description:

BACKGROUND OF THE INVENTION

[0001] 1. Field of the Invention

[0002] The field of application of the present invention is within the sector of the construction industry in general.

[0003] 2. Description of the Related Art

[0004] As is known, in the construction sector the installation of modular elements forming walls, partitions or other similar elements is increasingly more common, such elements being made with different materials alone or in combination with others, which incorporate ex-factory on an increasingly more frequent basis the conduits necessary for making connections to the different conventional utilities, as well as for accommodating the new and changing connection needs due to technological advancements.

[0005] The small dimensions that said construction materials usually have, especially adobe or ceramic brick, with considerable waste in their coupling, handling, placement and fixing once the work begins and throughout same for compartmentalizing, closing and dividing the different spaces therein, creating enclosures or rooms, represent an important factor to be taken into account, the solution to said problem being prefabricated modular elements.

[0006] However, the transport and handling of said elements within the construction site for lifting, positioning and fixing them generally entails tedious and delicate work due to the volume they occupy, the weight they may have, and the fragility of some of them, also entailing the investment of a considerable amount of time and manual labor, the objective of the present invention being to provide a practical, versatile, inexpensive and effective solution for said transport, handling, elevation, positioning, placement and/or fixing of said elements within the construction site.

[0007] In addition, it must be pointed out that today and in reference to the state of the art, the applicant is aware of the existence of inventions describing objects with a certain relevance with respect to the method herein proposed but the technical, structural and configuration features thereof are not at all similar to those of the invention herein proposed.

[0008] In this sense, document ES 2268910 must be mentioned, which belongs to the same applicant as the present invention and relating to a "Method for the construction and decoration of exterior fire-resistant enclosures during a pre-determined time period" and, as indicated by the title, relates to exterior enclosures and has considerable differences with respect to the one herein described, and document U.S. Pat. No. 3,494,091 must also be mentioned, which relates to a method of constructing houses, which discloses using a transfer truck for the transport, handling and positioning of slabs to form walls which also has considerable differences with respect to the invention herein described.

[0009] 3. Disclosure of the Invention

[0010] Therefore, the method for the transport, handling, positioning and fixing of floor-to-ceiling prefabricated construction elements to form fire-resistant internal walls or partitions in constructions of any type, including naval construction, proposed by the invention is configured as a novelty within its field of application, satisfactorily meeting the objectives previously indicated as being suitable because as a result of its creation, a system is specifically achieved which allows comfortably, quickly and simply moving, handling, lifting and placing the panels or prefabricated modular elements that will form the walls or partitions of the construction for which it is intended, the characterizing details making it possible being suitably included in the final claims attached to the present specification.

[0011] Specifically, the proposed method essentially comprises using a metal structure or transfer truck having an approximately prismatic configuration, having a front support base for incorporating the elements to be transported, which is provided in the lower portion with wheels manually operated by human or mechanical thrust or by a combination of both systems when the truck incorporates a crane, which will be explained below, furthermore having an articulated mechanism which allows extending and retracting support feet which increase the surface of contact with the floor for greater safety against overturning, being able to fix the equipment in a determined place when the work circumstances require doing so.

[0012] It is important to indicate that a small crane is incorporated on the mentioned transfer truck or structure for the handling, positioning and fixing of prefabricated elements having a weight exceeding 50 kg, and that said structure together with the mentioned crane will have dimensions and weights which allow it to work on the floor slabs or floor of any work site and to go through any door opening having standard measurements, which are usually about 2100 mm high and 900 mm wide.

[0013] In this sense, it should be pointed out that the dimensions of the assembly of the transfer structure plus the crane, where appropriate, will preferably be equal to or less than 1950 mm high and 900 mm wide, the measurements of the panels, boards or construction elements for which it is mainly intended being 3400 mm long (being able to be considerably greater in special circumstances), 600/900 mm wide and 60/70 mm thick.

[0014] It will also be taken into account that the sum of the construction elements to be transported plus the structure and, where appropriate, the crane will not exceed in each trip the maximum weight allowed by the floor slabs or floors of the building.

[0015] In turn, the mentioned crane is extendable and rotary, having at its end a hanging hook and a retaining bolt or pin intended for allowing the securing, lifting and rotation of the elements to be handled, said handling being the first step of the proposed method after the logical transfer of the element to its placement site.

[0016] In turn, for fixing the element, the placement of a screw or bolt fixed to the ceiling is provided first, to which screw or bolt there is incorporated on the part thereof that will be external to the ceiling a sleeve having an internal thread.

[0017] The placement of a bedplate, preferably of concrete, on the floor, fixed thereto by means of using corresponding screws and blocks, is also contemplated, having to point out that the passage of the electrical installation is provided for inside said bedplate, for which purpose said bedplate is provided with through holes traversing it longitudinally as well as with at least one access opening in its central area.

[0018] Once the mentioned screw of the ceiling and the bedplate of the floor are placed, the panel or construction element is positioned between them, which operation is performed manually or by means of operating the crane through the corresponding controls incorporated in the transfer truck or structure.

[0019] It is important to point out that in the upper edge of the panel there is incorporated a metal bracket having an inverted U section which will hold and block the joints of the panel in the upper part, being fitted by means of pressure to the aforementioned sleeve covering the bolt of the ceiling.

[0020] Furthermore, pressure and hanging hooks will be placed on the vertical sides of the panels, which will make the joints flush in addition to the previous function.

[0021] Next the space existing between the panel and the ceiling, and corresponding to the space occupied by the sleeve, is filled with concrete.

[0022] The panel is thereby duly placed, having intumescent joints on the floor and ceiling thereof which make it fire-resistant.

[0023] The described method for the transport, handling, positioning and fixing of floor-to-ceiling prefabricated construction elements to form fire-resistant internal walls or partitions in constructions of any type, including naval construction, represents innovative structure and constitutive features that have been unknown up until now for such purpose, and for these reasons as well as its practical usefulness, the invention has sufficient grounds to obtain the exclusive right that is sought.

SUMMARY OF THE INVENTION

[0024] As expressed by the title of the present specification, the invention relates to a method for the transport, handling, positioning and fixing of floor-to-ceiling prefabricated construction elements to form fire-resistant internal walls or partitions in constructions of any type, including naval construction.

[0025] Specifically, the object of the invention is focused on a method intended for transporting, handling, positioning and fixing floor-to-ceiling construction elements, which can be of two types:

[0026] a) up to 45/50 kg and,

[0027] b) more than 50 kg,

considering that those of type a) can be manually handled, positioned and fixed due to their reduced weight, and those of type b) must be handled, positioned and fixed with the aid of mechanical means due to their greater weight.

[0028] To that end, the proposed method essentially comprises using a metal structure or transfer truck having an approximately prismatic configuration, having a front support base for incorporating the elements to be transported, which is provided in the lower portion with wheels manually operated by human thrust or by a combination of both systems, and for the handling, positioning and fixing of elements of more than 50 kg the incorporation of a small crane on the mentioned structure is provided, said crane having dimensions and weights which allow it to work on the floor slabs or floor of any work site and to go through the door sill of any door having standard measurements, which are usually about 2100 mm high and 900 wide, the measurement of the panels preferably being about 3400 mm long or high (floor-to-ceiling), being able to be considerably longer in special circumstances and have widths between 300 to 450 mm for the lightest ones and 500 mm or more for those weighing more than 50 kg.

[0029] The process also comprises fixing the prefabricated elements to the floor and to the ceiling such that it has intumescent joints making them more fire-resistant.

BRIEF DESCRIPTION OF THE DRAWINGS

[0030] To complement the description that is being made and for the object of helping to better understand the features of the invention, a set of drawings is attached to the present specification as an integral part thereof in which the following has been depicted with an illustrative and non-limiting character:

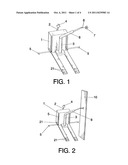

[0031] FIGS. 1 and 2 respectively show a perspective view of the transfer truck or structure with a crane the use of which contemplates the method object of the invention, and a view thereof in the use position, holding a prefabricated panel or construction element for which said method is intended.

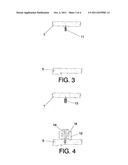

[0032] FIGS. 3 to 7 show respective section views of the different phases of assembly and fixing of the prefabricated panel or construction element according to the method of the invention

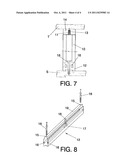

[0033] FIG. 8 shows a perspective view of the bedplate the use of which is provided for by the proposed method.

DETAILED DESCRIPTION OF THE EMBODIMENTS OF THE INVENTION

[0034] In view of the mentioned figures and according to the number used therein, it can be seen how the method for the transport, handling, positioning and fixing of floor-to-ceiling prefabricated construction elements to form fire-resistant internal walls or partitions in constructions of any type, including naval construction, proposed by the present invention essentially comprises using a transfer truck or structure (1), suitably provided with a front support base for incorporating the panels (10) or elements to be transported, which is provided in the lower portion with wheels (21) which can be manually operated by human or mechanical thrust or by a combination of both systems, as well as with an articulated mechanism which allows extending and retracting supplementary support feet (5) which increase the surface of contact with the floor, as observed in FIG. 1.

[0035] Continuing with said FIG. 1 and with FIG. 2, it can be seen how on the mentioned transfer truck or structure (1) optionally incorporates a small extendable rotary crane (3), especially for the handling, positioning, and fixing of elements weighing more than 50 kg, for which purpose it is provided with telescopic prolongations (8) and has a hanging hook (6) and a retaining bolt or pin (7) intended for holding the panel (10) to allow lifting and rotating them, said handling being the first step of the proposed method after the logical transfer of the element to its placement site.

[0036] It should further be mentioned that the transfer truck or structure (1) has a control gear (2) where the controls (4) for operating the crane (3) have been provided.

[0037] As observed in FIGS. 3 to 7, to fix the element (10), the proposed method first provides for the placement of a screw or bolt (11) fixed to the ceiling (T), to which screw or bolt there is incorporated on the part thereof that will be external to the ceiling a sleeve (13) having an internal thread.

[0038] The placement of a bedplate (12), preferably of concrete, on the floor (S), fixed by means of screws (18) inserted through vertical holes (15) provided for such purpose, is also contemplated, having to point out that the passage of the electrical installation is provided for inside said bedplate, for which purpose said bedplate is provided with through holes (16) traversing it longitudinally as well as with at least one access opening (17) in its central area, as can be seen in FIG. 8.

[0039] Once the mentioned screw (11) of the ceiling and the bedplate (12) of the floor are placed, the panel (10) or construction element is positioned between them, which operation in the event of elements weighing more than 50 kg is done by means of operating the crane (3) through the corresponding controls (4) incorporated in the transfer truck or structure (1).

[0040] It is important to point out that in the upper edge of the panel (10) there is incorporated a metal bracket (20) having an inverted U section which will hold and block the joints of the panel (10) in the upper part, being fitted by means of pressure to the aforementioned sleeve (13) covering the bolt (11) located in the ceiling.

[0041] Finally, the space (14) existing between the panel (10) and the ceiling, and corresponding to the space occupied by the sleeve (13), is filled with concrete.

[0042] In summary, the proposed method comprises using a transfer truck or structure (1), optionally provided with an extendable rotary crane (3) and provided with means for holding the panels (10) or construction elements to be handled, whereby performing the transfer and positioning of each panel (10) as a first step of the method; in that for fixing the element (10), there is provided the placement of a screw or bolt (11) fixed to the ceiling (T) to which there is incorporated, on the part thereof that is external to the ceiling, a sleeve (13) having an internal thread, and on the floor (S) the placement of a bedplate (12), preferably of concrete, fixed by means of screws (18) inserted through vertical holes (15) provided for such purpose; in that once the mentioned screw (11) of the ceiling and the bedplate (12) of the floor are placed, then the panel (10) or construction element is positioned between, in the upper edge of which there is incorporated a metal bracket (20) having an inverted U section, being fitted by means of pressure to the sleeve (13) covering the bolt (11) located in the ceiling; and finally in that the space (14) existing between the panel (10) and the ceiling, and corresponding to the space occupied by the sleeve (13), is filled with concrete.

[0043] Having sufficiently described the nature of the present invention and the manner of putting it into practice, it is not considered necessary to further explain the invention so that a person skilled in the art will understand its scope and the advantages that are derived from it, hereby stating that within its essential nature, it can be carried out to practice in other embodiments differing in detail from the one indicated by way of example and will also be covered by the protection sought provided that its essential principle is neither altered, changed nor modified.

User Contributions:

Comment about this patent or add new information about this topic: