Patent application title: FOOD PLATE WITH STRUCTURE FOR ACCOMMODATING FORK TINES

Inventors:

Moshe Ein-Gal (Ramat Hasharon, IL)

IPC8 Class: AA47G1902FI

USPC Class:

2205741

Class name: Receptacles table dish (e.g., plate, bowl, platter, etc.) with eating aid

Publication date: 2010-10-07

Patent application number: 20100252561

od plate including a plurality of slender

elements spanning over a surface for placing food thereon, wherein ends

of the slender elements are supported in a frame and wherein adjacent

slender elements are movable laterally with respect to one another so as

to accommodate various fork tine spacings.Claims:

1. An article comprising:a food plate comprising a plurality of slender

elements spanning over a surface for placing food thereon, wherein ends

of said slender elements are supported in a frame and wherein adjacent

slender elements are movable laterally with respect to one another so as

to accommodate various fork tine spacings.

2. The article according to claim 1, wherein said slender elements are parallel to one another.

3. The article according to claim 1, wherein said slender elements are made of a flexible material.

4. The article according to claim 1, wherein said slender elements are made of a rigid material and the ends of said slender elements are flexibly supported in said frame so that the ends can move sideways in said frame.

5. The article according to claim 1, wherein said slender elements comprise wires connected to an electrical source.Description:

CROSS-REFERENCE TO RELATED APPLICATIONS

[0001]This application is a continuation-in-part of U.S. patent application Ser. No. 12/054,534, filed Mar. 25, 2008, incorporated herein by reference.

FIELD OF THE INVENTION

[0002]The present invention relates generally to plates for food, and particularly to a food plate with structure for accommodating fork tines.

BACKGROUND OF THE INVENTION

[0003]Lifting small pieces of food, like chopped vegetable salad, peas, cherry tomatoes and the like, with a fork from a smooth plate is difficult due to low friction between food and plate surface. Since it is difficult to place the fork underneath the food, the food ends up being pushed by the fork all the way to the plate shoulder where it encounters horizontal resistance allowing it to be lifted by the fork.

SUMMARY OF THE INVENTION

[0004]The present invention seeks to provide an improved food plate that makes picking up pieces of food with a fork a simple and enjoyable task, as described more in detail hereinbelow.

[0005]There is thus provided in accordance with an embodiment of the present invention an article including a food plate including a plurality of slender elements spanning over a surface for placing food thereon, wherein ends of the slender elements are supported in a frame and wherein adjacent slender elements are movable laterally with respect to one another so as to accommodate various fork tine spacings.

[0006]In one embodiment, the slender elements are parallel to one another. In one embodiment, the slender elements are made of a flexible material. In another embodiment, the slender elements are made of a rigid material and the ends of the slender elements are flexibly supported in the frame so that the ends can move sideways in the frame.

[0007]In one embodiment, the slender elements include wires connected to an electrical source.

BRIEF DESCRIPTION OF THE DRAWINGS

[0008]The present invention will be understood and appreciated more fully from the following detailed description, taken in conjunction with the drawings in which:

[0009]FIG. 1 is a simplified pictorial illustration of a food plate, constructed and operative in accordance with an embodiment of the present invention, formed with furrows;

[0010]FIG. 2 is a simplified sectional illustration of the food plate of FIG. 1, taken along lines II-II in FIG. 2;

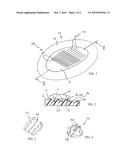

[0011]FIG. 3 is a simplified pictorial illustration of a food plate, constructed and operative in accordance with another embodiment of the present invention, formed with spaced spikes;

[0012]FIG. 4 is a simplified pictorial illustration of a food plate, constructed and operative in accordance with yet another embodiment of the present invention, formed with spaced bars; and

[0013]FIG. 5 is a simplified pictorial illustration of a food plate, constructed and operative in accordance with still another embodiment of the present invention, formed with spaced bars.

DETAILED DESCRIPTION OF EMBODIMENTS

[0014]Reference is now made to FIG. 1, which illustrates a food plate 10, constructed and operative in accordance with a non-limiting embodiment of the present invention.

[0015]Food plate 10 includes a surface 12 for placing food 14 thereon. Food plate 10 is of course constructed of a material suitable for serving food thereon, such as but not limited to, porcelain, plastic, stainless steel, wood and others. Surface 12 is corrugated with furrows 16, which may be formed by molding, machining, carving or any other suitable method. Furrows 16 define protrusions 17 and the spacing between adjacent furrows 16 or protrusions 17 equals a distance between tines 18 of a fork 20. The depth of the furrows 16 (i.e., height of the protrusions 17) is equal to or greater than a height of tines 18 of fork 20. Surface 12 may be bordered by a rim 15.

[0016]Food plate 10 may be further corrugated with furrows 16 on another surface 22 opposite to surface 12, as indicated by the broken lines in FIG. 2.

[0017]One or more heating wires 24 may be disposed in one or more protrusions 17 between adjacent furrows 16. Heating wires 24 may be connected to a power source (not shown) for heating plate 10.

[0018]Food plate 10 may be corrugated with at least two sets of furrows and protrusions, as shown in FIG. 1, wherein in one set 28 the furrows and protrusions are spaced from each other by a first distance and in another set 30 the furrows and protrusions are spaced from each other by a second distance different from the first distance. In this manner, different sets of tableware and cutlery can be accommodated by a single food plate. The food plate may be provided and sold as part of a tableware set, including one or more sets of forks matched to the furrows and protrusions.

[0019]Reference is now made to FIG. 3, which illustrates a food plate 32, constructed and operative in accordance with another embodiment of the present invention. Food plate 32, instead of having furrows like food plate 10, is formed with spaced spikes 34. In accordance with an embodiment of the invention, food plate 32 includes a matrix of spikes 34 arranged in rows and columns. The height of spikes 34 is generally equal to or greater than the fork tine height. The spacings between the rows and columns of the matrix are generally equal to fork inter-tines spacings, and may be different to accommodate different inter-tines spacings. It is noted that "spike" 34 can be pointed, but alternatively can be rounded, and in general can have a variety of shapes and sizes.

[0020]Reference is now made to FIG. 4, which illustrates a food plate 36, constructed and operative in accordance with yet another embodiment of the present invention. Food plate 36 includes parallel bars 38, which may be held and connected by cross-bars 40 at both ends thereof. The height of parallel bars 38 is generally equal to or greater than the fork tine height. The inter-bars spacing is generally equal to a fork inter-tines spacing, and may be different to accommodate different inter-tines spacings. The bars 38 and 40 can have a variety of shapes and sizes.

[0021]Reference is now made to FIG. 5, which illustrates a food plate 50, constructed and operative in accordance with still another embodiment of the present invention. Food plate 50 includes a plurality of slender elements 52 (such as, but not limited to, rods, bars, wires and the like) spanning over a surface 53 for placing food thereon. Adjacent slender elements 52 are movable laterally with respect to one another as to accommodate various fork tine spacings. Slender elements 52 are preferably parallel to one another. The wires can be made of a flexible material, e.g., silicone, or of a rigid material, e.g., stainless steel, flexibly supported at the ends 54 so as to enable and permit lateral motion. (That is, ends 54 can move sideways in a frame 56.) Particularly in the case of metal or other conducting material, the wires can be used to heat the food placed on the wires (e.g., the wires can be connected to an electrical source 58, such as a battery or mains, to provide electrical resistance heating). Alternatively, heating wires can be connected to electrical source 58 and pass through the slender elements 52.

[0022]All the embodiments of the invention may be constructed as an integral part of a plate. Alternatively, any of the embodiments of the invention may be constructed as an insert designed to be placed in a conventional plate. Accordingly, the insert of the embodiment of FIG. 1 would have furrows as shown, the insert of FIG. 3 would have spikes, the insert of FIG. 4 would have bars, and the insert of FIG. 5 would have the slender elements. As before, the inserts would of course be constructed of a material suitable (hygienic) for serving food thereon, such as but not limited to, porcelain, plastic, stainless steel, wood and others. The inserts may be disposable.

[0023]The present invention may be used with a fork with sharp-tipped tines or with round-tipped tines. Thus the present invention provides a safety feature of permitting use of a safety fork with rounded tips, designed to lift food from a plate with furrows, spikes or adequate inserts. Prior art plates are not so useful with such round-tipped forks. Round-tipped forks are described, for example, in U.S. Pat. No. 4,896,423 to Kinsey, the disclosure of which is incorporated herein by reference.

[0024]The scope of the present invention includes both combinations and subcombinations of the features described hereinabove as well as modifications and variations thereof which would occur to a person of skill in the art upon reading the foregoing description and which are not in the prior art.

Claims:

1. An article comprising:a food plate comprising a plurality of slender

elements spanning over a surface for placing food thereon, wherein ends

of said slender elements are supported in a frame and wherein adjacent

slender elements are movable laterally with respect to one another so as

to accommodate various fork tine spacings.

2. The article according to claim 1, wherein said slender elements are parallel to one another.

3. The article according to claim 1, wherein said slender elements are made of a flexible material.

4. The article according to claim 1, wherein said slender elements are made of a rigid material and the ends of said slender elements are flexibly supported in said frame so that the ends can move sideways in said frame.

5. The article according to claim 1, wherein said slender elements comprise wires connected to an electrical source.

Description:

CROSS-REFERENCE TO RELATED APPLICATIONS

[0001]This application is a continuation-in-part of U.S. patent application Ser. No. 12/054,534, filed Mar. 25, 2008, incorporated herein by reference.

FIELD OF THE INVENTION

[0002]The present invention relates generally to plates for food, and particularly to a food plate with structure for accommodating fork tines.

BACKGROUND OF THE INVENTION

[0003]Lifting small pieces of food, like chopped vegetable salad, peas, cherry tomatoes and the like, with a fork from a smooth plate is difficult due to low friction between food and plate surface. Since it is difficult to place the fork underneath the food, the food ends up being pushed by the fork all the way to the plate shoulder where it encounters horizontal resistance allowing it to be lifted by the fork.

SUMMARY OF THE INVENTION

[0004]The present invention seeks to provide an improved food plate that makes picking up pieces of food with a fork a simple and enjoyable task, as described more in detail hereinbelow.

[0005]There is thus provided in accordance with an embodiment of the present invention an article including a food plate including a plurality of slender elements spanning over a surface for placing food thereon, wherein ends of the slender elements are supported in a frame and wherein adjacent slender elements are movable laterally with respect to one another so as to accommodate various fork tine spacings.

[0006]In one embodiment, the slender elements are parallel to one another. In one embodiment, the slender elements are made of a flexible material. In another embodiment, the slender elements are made of a rigid material and the ends of the slender elements are flexibly supported in the frame so that the ends can move sideways in the frame.

[0007]In one embodiment, the slender elements include wires connected to an electrical source.

BRIEF DESCRIPTION OF THE DRAWINGS

[0008]The present invention will be understood and appreciated more fully from the following detailed description, taken in conjunction with the drawings in which:

[0009]FIG. 1 is a simplified pictorial illustration of a food plate, constructed and operative in accordance with an embodiment of the present invention, formed with furrows;

[0010]FIG. 2 is a simplified sectional illustration of the food plate of FIG. 1, taken along lines II-II in FIG. 2;

[0011]FIG. 3 is a simplified pictorial illustration of a food plate, constructed and operative in accordance with another embodiment of the present invention, formed with spaced spikes;

[0012]FIG. 4 is a simplified pictorial illustration of a food plate, constructed and operative in accordance with yet another embodiment of the present invention, formed with spaced bars; and

[0013]FIG. 5 is a simplified pictorial illustration of a food plate, constructed and operative in accordance with still another embodiment of the present invention, formed with spaced bars.

DETAILED DESCRIPTION OF EMBODIMENTS

[0014]Reference is now made to FIG. 1, which illustrates a food plate 10, constructed and operative in accordance with a non-limiting embodiment of the present invention.

[0015]Food plate 10 includes a surface 12 for placing food 14 thereon. Food plate 10 is of course constructed of a material suitable for serving food thereon, such as but not limited to, porcelain, plastic, stainless steel, wood and others. Surface 12 is corrugated with furrows 16, which may be formed by molding, machining, carving or any other suitable method. Furrows 16 define protrusions 17 and the spacing between adjacent furrows 16 or protrusions 17 equals a distance between tines 18 of a fork 20. The depth of the furrows 16 (i.e., height of the protrusions 17) is equal to or greater than a height of tines 18 of fork 20. Surface 12 may be bordered by a rim 15.

[0016]Food plate 10 may be further corrugated with furrows 16 on another surface 22 opposite to surface 12, as indicated by the broken lines in FIG. 2.

[0017]One or more heating wires 24 may be disposed in one or more protrusions 17 between adjacent furrows 16. Heating wires 24 may be connected to a power source (not shown) for heating plate 10.

[0018]Food plate 10 may be corrugated with at least two sets of furrows and protrusions, as shown in FIG. 1, wherein in one set 28 the furrows and protrusions are spaced from each other by a first distance and in another set 30 the furrows and protrusions are spaced from each other by a second distance different from the first distance. In this manner, different sets of tableware and cutlery can be accommodated by a single food plate. The food plate may be provided and sold as part of a tableware set, including one or more sets of forks matched to the furrows and protrusions.

[0019]Reference is now made to FIG. 3, which illustrates a food plate 32, constructed and operative in accordance with another embodiment of the present invention. Food plate 32, instead of having furrows like food plate 10, is formed with spaced spikes 34. In accordance with an embodiment of the invention, food plate 32 includes a matrix of spikes 34 arranged in rows and columns. The height of spikes 34 is generally equal to or greater than the fork tine height. The spacings between the rows and columns of the matrix are generally equal to fork inter-tines spacings, and may be different to accommodate different inter-tines spacings. It is noted that "spike" 34 can be pointed, but alternatively can be rounded, and in general can have a variety of shapes and sizes.

[0020]Reference is now made to FIG. 4, which illustrates a food plate 36, constructed and operative in accordance with yet another embodiment of the present invention. Food plate 36 includes parallel bars 38, which may be held and connected by cross-bars 40 at both ends thereof. The height of parallel bars 38 is generally equal to or greater than the fork tine height. The inter-bars spacing is generally equal to a fork inter-tines spacing, and may be different to accommodate different inter-tines spacings. The bars 38 and 40 can have a variety of shapes and sizes.

[0021]Reference is now made to FIG. 5, which illustrates a food plate 50, constructed and operative in accordance with still another embodiment of the present invention. Food plate 50 includes a plurality of slender elements 52 (such as, but not limited to, rods, bars, wires and the like) spanning over a surface 53 for placing food thereon. Adjacent slender elements 52 are movable laterally with respect to one another as to accommodate various fork tine spacings. Slender elements 52 are preferably parallel to one another. The wires can be made of a flexible material, e.g., silicone, or of a rigid material, e.g., stainless steel, flexibly supported at the ends 54 so as to enable and permit lateral motion. (That is, ends 54 can move sideways in a frame 56.) Particularly in the case of metal or other conducting material, the wires can be used to heat the food placed on the wires (e.g., the wires can be connected to an electrical source 58, such as a battery or mains, to provide electrical resistance heating). Alternatively, heating wires can be connected to electrical source 58 and pass through the slender elements 52.

[0022]All the embodiments of the invention may be constructed as an integral part of a plate. Alternatively, any of the embodiments of the invention may be constructed as an insert designed to be placed in a conventional plate. Accordingly, the insert of the embodiment of FIG. 1 would have furrows as shown, the insert of FIG. 3 would have spikes, the insert of FIG. 4 would have bars, and the insert of FIG. 5 would have the slender elements. As before, the inserts would of course be constructed of a material suitable (hygienic) for serving food thereon, such as but not limited to, porcelain, plastic, stainless steel, wood and others. The inserts may be disposable.

[0023]The present invention may be used with a fork with sharp-tipped tines or with round-tipped tines. Thus the present invention provides a safety feature of permitting use of a safety fork with rounded tips, designed to lift food from a plate with furrows, spikes or adequate inserts. Prior art plates are not so useful with such round-tipped forks. Round-tipped forks are described, for example, in U.S. Pat. No. 4,896,423 to Kinsey, the disclosure of which is incorporated herein by reference.

[0024]The scope of the present invention includes both combinations and subcombinations of the features described hereinabove as well as modifications and variations thereof which would occur to a person of skill in the art upon reading the foregoing description and which are not in the prior art.

User Contributions:

Comment about this patent or add new information about this topic: